I introduce the crankshaft as the heart of an engine. It turns the up and down motion of pistons into rotation. This rotation is what makes the car move.

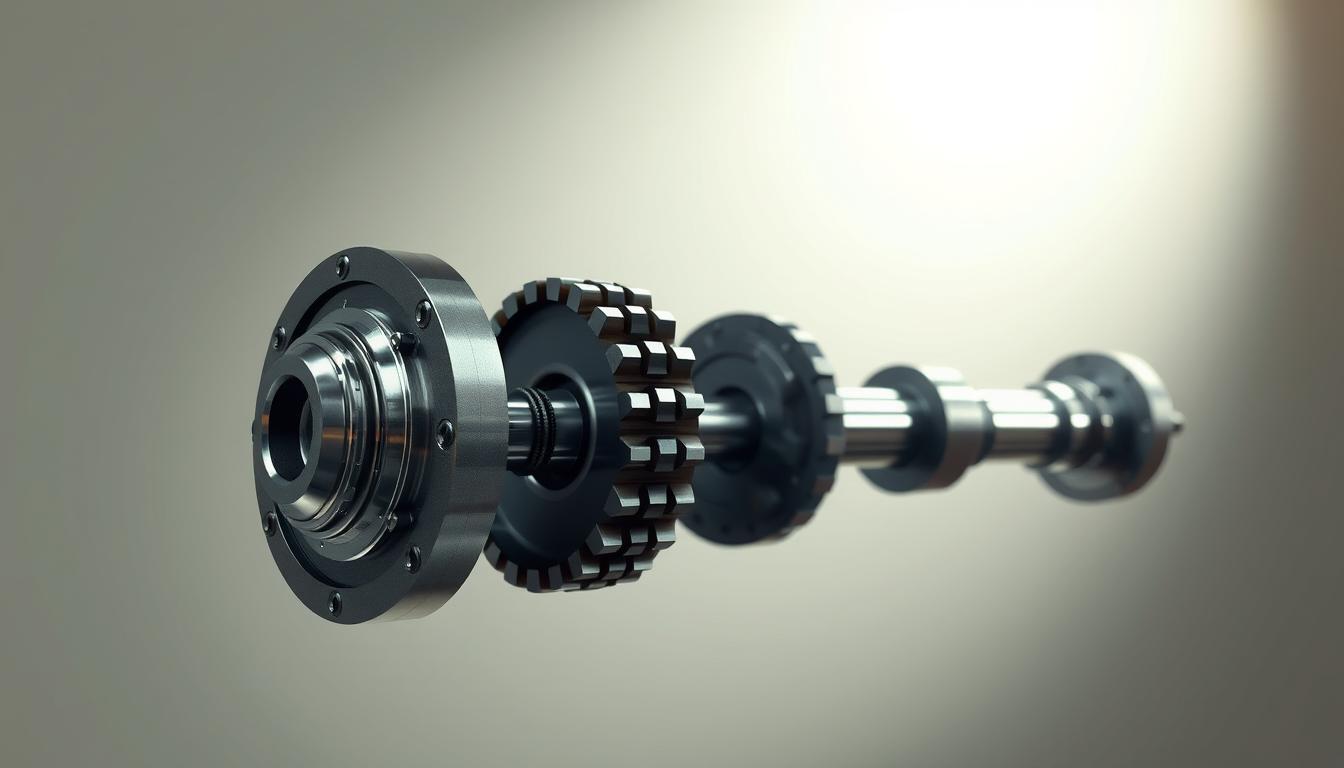

The crankshaft has key parts like main journals and counterweights. It sits in the engine block and connects to pistons through rods. This setup is essential for the engine’s function.

I explain how it works: pistons move, rods push the crankpins, and this creates torque. This is the force that makes the car move. There are different types of crankshafts, each suited for specific engines.

Engine layouts, like inline or V, affect how the crankshaft works. The firing order and journal phasing are important for smoothness. The crankshaft is vital in many industries, including cars and trucks.

Knowing about crankshafts is key. They impact how well an engine performs and how quiet it is. Understanding this helps us appreciate the engine’s complexity.

Crankshaft: core function and role in the engine:

The crankshaft is the engine’s heart, turning piston motion into rotation. It uses crank throws as levers to convert force into torque. This process happens over and over, powering the drivetrain.

Connecting rod angles affect the crank’s leverage. When the rod is vertical, the crank gets more force. As it angles, the torque drops. The crankshaft smooths out these changes to keep power steady.

Phasing and firing order are key. They determine when each cylinder fires. This even spacing reduces vibration and makes the engine feel smoother. The firing order also affects how torque is produced.

Rotational speed has limits to avoid damage. As RPM increases, so do inertial loads. Counterweights help, but going too fast can cause bending or cracks.

Crankshaft balance is vital. Counterweights and journal positioning reduce shaking. Inline engines focus on primary forces, while V engines deal with secondary effects. Engineers use counterweights and firing order to balance forces.

Torsional behavior is important. Harmonic dampers and flywheels absorb pulses. This reduces stress on the crankshaft, extending its life.

Ignoring vibration can harm durability. Bearings wear out faster, and small cracks can grow. Designing for balance and using dampers helps engines last longer.

Design and materials used in crankshaft manufacturing:

I explore the materials used in crankshaft making. Forged steel, like 4140 or 4340 alloy, is top for strength and durability. Brands like Ford and Toyota often pick forged crankshafts for their trucks and high-performance engines.

Cast iron is used in cheaper engines where saving money and handling vibrations are key.

Next, I talk about how crankshafts are made. Cast crankshafts are made by pouring and machining, which is cheaper for making lots of parts. Forged crankshafts, made by compressing metal, are stronger.

For top racing or custom engines, CNC mills and grinders shape tool steel bars into billet crankshafts.

Surface treatments make crankshafts last longer. Carburizing and nitriding are two ways to make them stronger. Carburizing creates a hard outer layer on steel, while nitriding hardens the surface without warping it. Induction hardening adds strength to specific parts of cast crankshafts.

Finishing touches are important for performance and oiling. Grinding and polishing journals, balancing counterweights, and drilling precise oil holes help. Shot peening is also used to prevent cracks by adding compressive stress to the surface.

Design choices affect how well a crankshaft works. Things like journal sizes, fillet radii, and counterweight sizes impact its strength. Oil hole placement and the slenderness ratio also play a role in how it flexes and stays lubricated.

Trade-offs are clear: forged crankshafts handle high RPMs and heavy loads well. Cast crankshafts are cheaper and work fine for everyday use.

I also talk about industry practices and who supplies what. Big car makers choose materials based on what they need, cost, and weight. Aftermarket brands offer billet crankshafts for extreme builds that need custom profiles and higher strength.

Crankshaft installation and alignment considerations:

I start every crankshaft installation with a thorough check. I look for any damage on the journals and measure their sizes. I also check the main bearing bores for any issues.

I use a dial indicator to check the crankshaft’s alignment. This makes sure it meets the engine maker’s standards.

Choosing the right bearings is key for good oil flow and long life. I use plastigage or micrometers to set the oil clearance. This ensures the engine runs smoothly under load.

When installing the crankshaft, I follow a specific order and use the right torque. I install main caps in the correct sequence and use the specified torque. For torque-to-yield fasteners, I use new bolts and follow the exact instructions.

I also prepare the threads with the right cleaning and lubrication. This is based on the manual’s instructions.

Aligning the crankshaft is important. I check the endplay and runout with a dial indicator. I set the thrust bearings as specified. I compare the runout values to the service manual to ensure everything is correct.

Cleaning and lubricating the oil passages is part of my routine. I make sure the oil holes are clear and prime the oiling system. I also apply assembly lube to the journals and bearings for the first start-up.

Keeping the work area clean and following exact tolerances is important. Improper clearances, mis-torqued caps, contaminated bearings, or incorrect thrust setup can cause problems. I double-check everything to avoid these issues.

Using the right tools is essential for reliable work. I need micrometers, telescoping gauges, plastigage, a dial indicator, a calibrated torque wrench, and an engine hoist. I also make sure the assembly area is spotless to protect the bearings and journals.

Common failure modes and wear patterns of crankshafts:

I look into how crankshafts fail in real engines and where to start. Fatigue cracks often start at specific points like fillet radii or oil holes. I check for cracks at main-to-throw transitions and counterweight webs. Tiny hairline fractures can grow with each load cycle.

I talk about wear caused by bearings and why it happens. Issues like oil starvation, contamination, or low pressure can cause metal transfer. This leads to journal scoring and marks on the journal surface.

Surface damage comes in different forms. Scoring follows debris paths, while pitting can be caused by corrosion. Heat discoloration may appear before micro-seizure. Each damage type changes the wear patterns of the crankshaft.

Torsional failure is a big concern in high-performance and diesel engines. High cyclic torque can cause fractures through torsional fatigue. Harmonic dampers and proper balancing help prevent this. I look for abrupt breaks and matching fracture faces in such cases.

Spotting problems early can save on repair costs and downtime. I watch for signs like metallic knocking, low oil pressure, or coolant contamination. Unusual vibration and visible metal in oil are also red flags.

I explain how to inspect and repair crankshafts accurately. Magnetic particle inspection and magnaflux find surface and near-surface cracks. Ultrasonic testing finds deeper flaws. Grinding journals and replacing bearings can restore serviceability. Replacement is needed when cracks or distortion are too severe.

Keeping the crankshaft running long depends on good lubrication, regular maintenance, and operating conditions. Using the right oil and following maintenance schedules helps. Clean filters and correct bearing clearances also play a role in preventing wear.

Performance tuning and aftermarket crankshaft options:

I help readers find ways to boost power and RPM stability. Upgrading to a forged steel or billet crankshaft can improve strength. A stroker crank increases torque but also raises piston speed and stress on engine parts.

Opting for a lightweight crank can make your engine respond quicker. But, it might send more vibrations to the block and drivetrain. It’s important to balance and dampen these effects properly.

For engines running at high RPM, a performance crankshaft is safer. It’s designed to handle the stress of high speeds without failing.

Balance is key. I suggest balancing the entire engine assembly, including the crank, pistons, rods, and flywheel. This reduces vibration and stress on bearings. Static balancing alone isn’t enough, as it misses important dynamic behaviors.

Before installing, check if the crankshaft fits. Look at journal sizes, oiling passages, and crank harmonics. Installing a stroker crank might need changes to pistons, rods, and flywheels.

I recommend parts from trusted brands like Callies, Scat, Eagle, Crower, and Carrillo. They offer strong and durable crankshafts. Their specs help match the crank to bearings and rods.

When choosing, think about the engine’s RPM range, boost level, and use. Match the crank to your engine’s needs, whether for street, drag, or racing. Don’t forget to upgrade main and rod bolts, bearings, dampers, and flywheels for durability.

When deciding, weigh strength, weight, and noise. Billet cranks are strong and easy to balance. Stroker cranks boost torque but need careful consideration of piston speed and ring life. Choose a crankshaft that fits your engine’s overall plan, not just one aspect.

Maintenance tips and diagnostic checks for longevity:

I suggest changing oil and filters often to protect the crankshaft. I follow API and SAE guidelines for oil choice. Using the right oil viscosity and grade helps keep the crankshaft running smoothly.

Regular crankshaft checks are key. I watch oil pressure, listen for unusual sounds, and check for metal in oil filters. Oil analysis for wear metals like iron and copper helps spot problems early. I also inspect bearings during major services.

For detailed checks, I use dial indicators and a borescope. These tools help me measure crank endplay and inspect journal surfaces. I also do vibration analysis to catch torsional issues. Preventative maintenance includes proper break-in, correct fastener torque, and timely replacement of parts.

I keep an eye on cooling and combustion to prevent oil contamination. Avoiding coolant leaks and detonation reduces stress on the crank. If I see scoring or cracks, I decide on regrind or full replacement. I recommend professional inspection if there’s vibration or noise.