In this article, I will guide you through the centrifugal compressor alignment process. This is key for keeping compressors running at their best. These machines are vital in many industries, so aligning them correctly is critical. It helps them work efficiently and last longer.

We will look at the technical details, step-by-step procedures, and top tips for aligning these compressors. This will help you understand how to do it right.

Understanding Centrifugal Compressors:

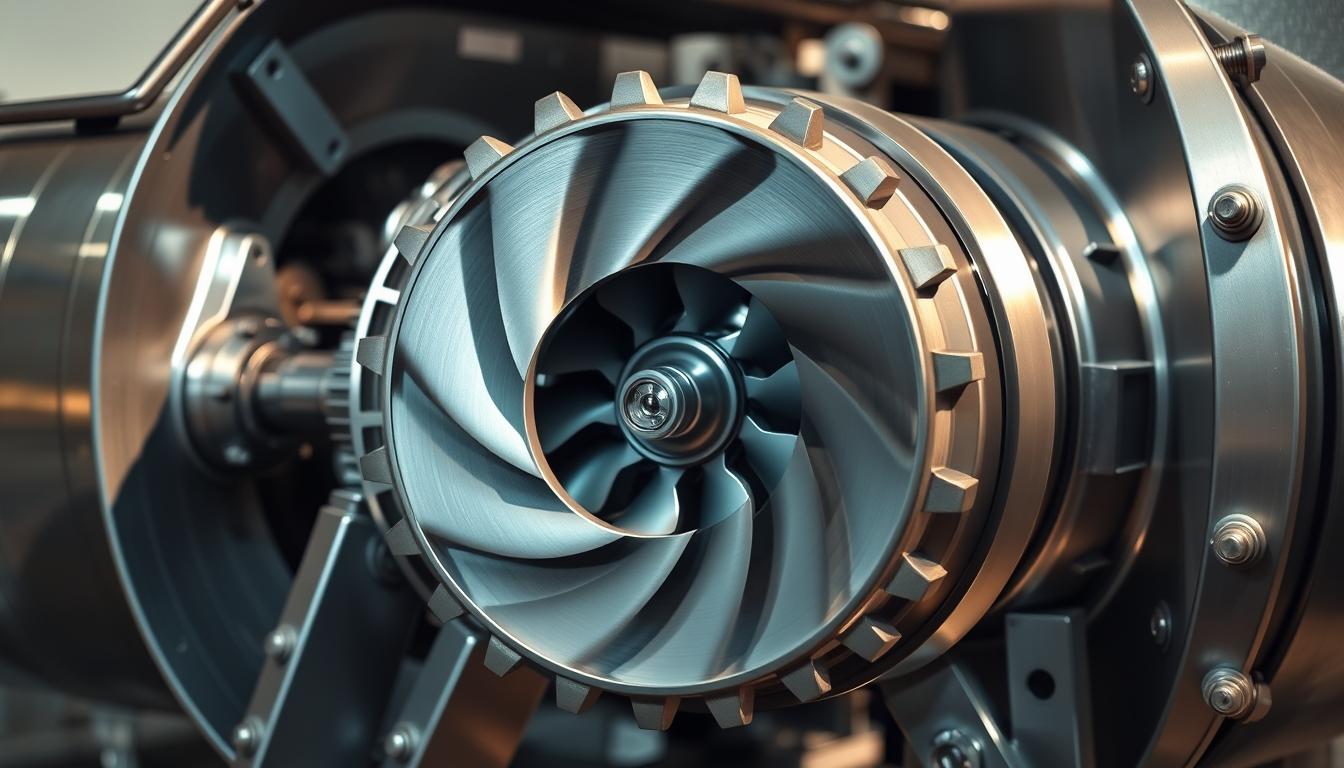

Centrifugal compressors are key in many industries. They work by changing kinetic energy into pressure energy, making airflow more efficient.

Important parts like impellers, diffusers, and volutes work together. The impeller speeds up the gas, and the diffuser turns that speed into pressure. Knowing how these parts work helps us see how compressors manage airflow in places like HVAC and power plants.

Importance of Proper Alignment:

In my experience, the compressor alignment significance is huge for centrifugal compressors. Proper alignment is key for these machines to work well. Misalignment can cause too much vibration, wear down parts, and even lead to big failures.

Getting the alignment right boosts performance. When compressors are aligned well, they use less energy and produce more. This means lower costs and better profits, which is vital for success.

Also, fixing alignment problems early can stop frequent repairs and downtime. This approach makes operations safer over time. In short, keeping alignment right is critical for keeping centrifugal compressors running smoothly and effectively.

Centrifugal Compressor Alignment Procedure:

Aligning centrifugal compressors is key for their best performance. First, I check the foundation and make sure the compressor is firmly mounted. A solid base helps avoid misalignment, which can cause big problems.

Then, I use dial indicators or laser systems to check the shafts’ alignment. These tools help get a precise alignment for efficient work. I take readings from both shafts to spot any misalignment.

After taking measurements, I adjust the compressor’s position. I make small changes to the baseplate or mounting pads based on the readings. This step needs careful attention because small changes can make a big difference.

Lastly, I verify the alignment after making adjustments. Getting the alignment right is important to reduce vibration and extend the compressor’s life. This confirms the compressor is aligned and ready to work.

Pre-Alignment Checks:

Before starting the alignment process, I do a detailed check to make sure everything is ready. These checks are key to avoiding problems later. First, I inspect the compressor and its parts. I check if the foundation is stable, as a solid base is critical for good alignment.

Then, I look at the mounting surfaces for dirt and flatness. Any dirt or unevenness can mess up the alignment. So, I clean and get these surfaces ready carefully. I also fix any mechanical issues that could affect the alignment. These steps are important for a smooth alignment process. By doing these checks first, I make sure the alignment goes well, reducing errors and improving efficiency.

Types of Alignment Methods:

In my work with centrifugal compressors, I’ve seen many alignment techniques. The straight edge method is simple but might not catch all misalignments. It’s good for a quick check but not perfect.

Laser alignment is more precise. It uses lasers to measure how well machinery is aligned. This method shows the results on a screen, making it easy to see if things are off.

Dial indicators are also useful. They measure how much a shaft is out of place. This helps fix both kinds of misalignment. It’s a key tool for getting the compressor running smoothly.

Choosing the right alignment method depends on the situation. Each has its own strengths and weaknesses. Knowing these can help make compressors more reliable and efficient.

Post-Alignment Adjustments:

After aligning a centrifugal compressor, making post-alignment adjustments is key for top performance. I focus on fine-tuning any issues to get the precision needed. The process involves checking the alignment under different conditions.

Monitoring the compressor’s performance is a top choice for adjustments. I look at vibration and temperature data to spot any misalignments. These checks confirm that all adjustments are done right, ensuring the compressor works well.

Using best practices in post-alignment adjustments boosts the equipment’s life and reduces future problems. A careful approach ensures each compressor works well and efficiently.

Common Mistakes to Avoid:

When aligning centrifugal compressors, I often see mistakes that can hurt performance. One big problem is using the wrong measurement tools. If I use old or wrong tools, the whole process can fail.

Another mistake is skipping important checks before starting. Not checking the baseline can lead to big problems. I’ve found that checking everything first can uncover issues and make the alignment better.

Also, ignoring how temperature changes can affect alignment is a big mistake. I need to remember that temperature changes can cause misalignment. If I don’t watch for this, I might face problems later.

By knowing these common mistakes, I can do a better job of aligning compressors. This helps make the systems work more efficiently and last longer.

Regular Maintenance Practices:

Keeping centrifugal compressors in top shape is key to their long life and good performance. I stick to a few important steps to keep them running smoothly. Regular checks help spot problems before they get big.

Checking alignment, vibration, and lubrication is a must. This keeps the compressor working at its best. A proactive maintenance plan is also vital. I make sure to oil the compressors regularly to prevent wear.

By following these maintenance steps, I keep centrifugal compressors efficient and reliable. A consistent maintenance routine boosts performance and cuts down on unexpected stops. This leads to more productive work.

Conclusion and Best Practices for Alignment:

Proper alignment in centrifugal compressors is key for top performance. This article has covered important steps for alignment. By focusing on precise alignment, we boost efficiency and extend equipment life.

My last thoughts are about the need for detailed checks before alignment. It’s also important to choose the right methods and make careful adjustments after. Regular upkeep boosts compressor reliability in many industries.

Let’s all follow a systematic approach to alignment. This ensures compressors work at their best. Accurate alignment is a vital investment in our machinery’s performance.