In the world of fluid mechanics, knowing how to calculate centrifugal pumps is key. These pumps are vital in many industries, helping move liquids around. By learning about these calculations, we can make pumps work better and avoid big problems.

Understanding these calculations is a must for engineers and technicians. It helps them design and run systems well. This knowledge is essential for making sure everything works smoothly.

Understanding the Basics of Centrifugal Pumps:

Centrifugal pumps work by using fluid dynamics. They use the force of rotation to move fluids efficiently. This design changes energy into fluid movement, which is important in many uses.

I look at the basics of head, flow rate, and pressure in pump operation. These are key to understanding how centrifugal pumps work.

The head of a pump is how high it can lift a fluid. Flow rate is the volume of fluid it can move over time. Pressure is the force of the fluid in motion. These are all connected and affect the pump’s performance.

Viscosity and density are also important. Viscosity is how a fluid resists flow. Density is how much energy it takes to move it. Knowing these helps choose the right pump for a job.

I compare positive displacement and centrifugal pumps. Positive displacement pumps trap and push fluid, while centrifugal pumps use rotation for flow. This shows centrifugal pumps are versatile for many uses.

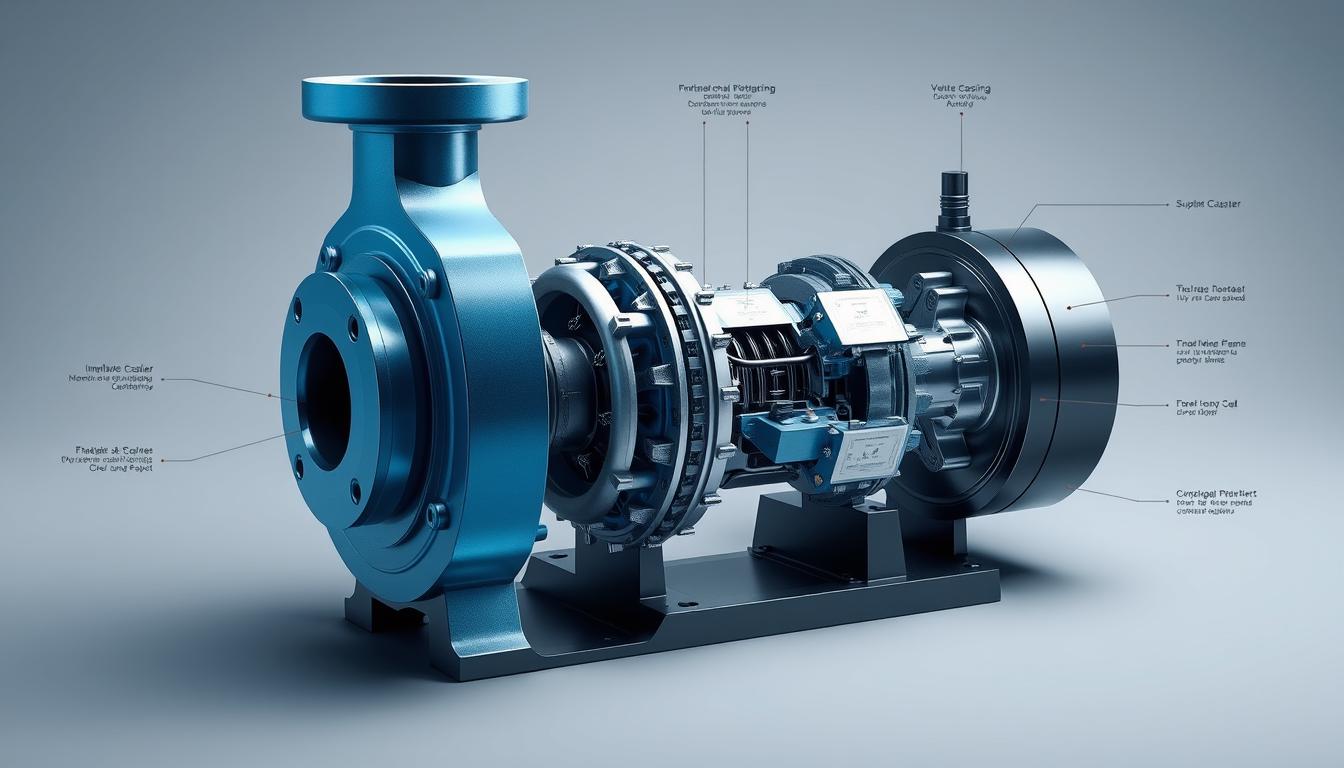

Key Components of a Centrifugal Pump:

A centrifugal pump works well because of its key parts. I’ll talk about the impeller, casing, shaft, and mechanical seals. Each part is important for the pump to work right.

The impeller is the pump’s core. It turns mechanical energy into kinetic energy. Its design affects how much fluid it can move and the pressure it can create. There are different impeller designs for different needs and fluids.

The casing is around the impeller. It guides the liquid flow to the right pressure. The casing’s shape and size are important for the pump’s performance and energy use.

The shaft links the impeller to the motor. It carries the energy needed for the pump to work. It must be strong to handle the stress and wear it faces.

Knowing about these parts helps me see why choosing the right materials is important. The material affects how long the pump lasts and how well it works. This also impacts how often it needs maintenance and troubleshooting.

Centrifugal Pump Calculation Methodologies:

In this section, I will outline the various methodologies employed for effective centrifugal pump calculations. Understanding the basic formulas for determining flow rate is key in hydraulic design. Flow rate affects pump performance, impacting both efficiency and system reliability.

Head calculations, like total dynamic head (TDH), are also critical. TDH is the energy needed to overcome all system resistances. It’s essential for a pump’s performance.

Calculating pump horsepower requirements is vital. This ensures pumps are neither too small nor too large. Using the affinity laws helps adjust pump performance under different conditions.

Accurate data is essential for these calculations. Using precise information ensures reliable pump selection and enhances hydraulic design. A rigorous approach to data accuracy leads to optimal pump performance and longevity.

Hydraulic Principles Behind Pump Operation:

The way centrifugal pumps work is based on key hydraulic principles. These principles tell us how fluids act under different conditions. Bernoulli’s equation is a big part of this, showing how energy is saved in fluid mechanics.

This equation helps us see how energy changes as fluids move. It shows the balance between kinetic, gravitational, and pressure energy. This balance is key to understanding how pumps work.

When looking at pump performance, I think about pressure drops and friction losses. These are big factors that affect how well a pump works. The speed of the fluid flow also matters, as it affects pressure.

Higher speeds mean more kinetic energy but also more friction. Finding the right balance is important for choosing and setting up pumps.

Knowing these hydraulic principles is vital for many uses. This includes water treatment, chemical processing, and HVAC systems. By using Bernoulli’s equation and understanding pressure and velocity, we can design better pumps.

Factors Influencing Centrifugal Pump Performance:

Fluid properties are key in understanding centrifugal pump performance. Viscosity, density, and temperature affect how the pump works and its efficiency. For instance, thicker fluids need more energy to move, which can lower the pump’s performance.

Pump speed also matters a lot. When I increase the speed, the flow rate often goes up. But, this can also wear down the pump’s parts. So, knowing how speed affects efficiency is important for the best results.

Other factors like impeller design and system layout also play a big role. A good impeller design can improve performance. But, a bad piping layout can slow down fluid flow.

Cavitation is another thing I watch out for. It happens when vapor bubbles form and then collapse, causing damage and performance loss. By addressing these issues, we can make the pump work better and last longer.

Determining Pump Efficiency:

To understand pump efficiency, we need to look at hydraulic and volumetric efficiency. Hydraulic efficiency shows how well the pump uses energy. It’s found by comparing the energy it uses to the energy it produces. Volumetric efficiency checks if the pump moves the right amount of fluid. It compares the actual flow to what it should be.

When we look at both, we get a full picture of the pump’s performance. This shows how energy is used and lost. Setting standards for these measurements helps find ways to improve. Regular checks on efficiency save energy and cut costs, making systems work better.

From my experience, paying close attention to these metrics helps make better choices. Knowing these details helps improve systems. Following the best practices keeps efficiency high, driving innovation and better performance.

Common Mistakes in Centrifugal Pump Calculations:

In my work with centrifugal pump calculations, I’ve seen many mistakes. One big issue is ignoring pump curves. These curves are key to knowing how a pump works. Without them, we can’t accurately figure out flow rates and head, which hurts system performance.

Another common mistake is forgetting about friction losses in pipes. These losses can make a system less efficient and use more energy. This happens when we don’t have the right info on pipe length, diameter, and material.

These mistakes can cause real problems. I’ve seen cases where not double-checking calculations led to pump issues. This caused downtime and higher costs. I want to help others avoid these mistakes, so we can all work with centrifugal pumps more effectively.

Technology and Software in Pump Calculations:

Modern technology and software have greatly improved centrifugal pump calculations. Pump calculation software makes complex tasks easier, reducing errors. It also boosts accuracy. I use specialized engineering tools for hydraulic modeling and to simulate different scenarios.

These tools simplify calculations and show hydraulic systems visually. This makes it easier to understand and share pump performance. Predictive maintenance technologies are also key for better pump efficiency. They help me spot issues early and prevent them, keeping pumps running smoothly for a long time.

Real-World Applications of Centrifugal Pumps:

Centrifugal pumps are key in many industries. They are used in water treatment to move water through purification stages. This ensures water quality remains high. Their role in managing water resources is vital for sustainable practices.

In agriculture, these pumps are vital for irrigation. They move water from rivers or reservoirs to crops. Pumps are designed for different crops and soil types, boosting productivity. This shows how adaptable centrifugal pumps are for various farming conditions.

In the chemical processing industry, pumps are essential for moving thick liquids and chemicals. They are made to resist corrosion, making it safe to handle dangerous substances. Choosing the right pumps improves safety and efficiency in production. These examples highlight the importance of centrifugal pumps in many sectors, showing their role in fluid transport systems.