I want to explain why strong pressure vessel design is key. It’s for safety, reliability, and to keep operations running smoothly. This is true in places like chemical plants, power stations, and factories in the U.S. Good design means less downtime, fewer repairs, and no big fines. It also keeps people and things safe.

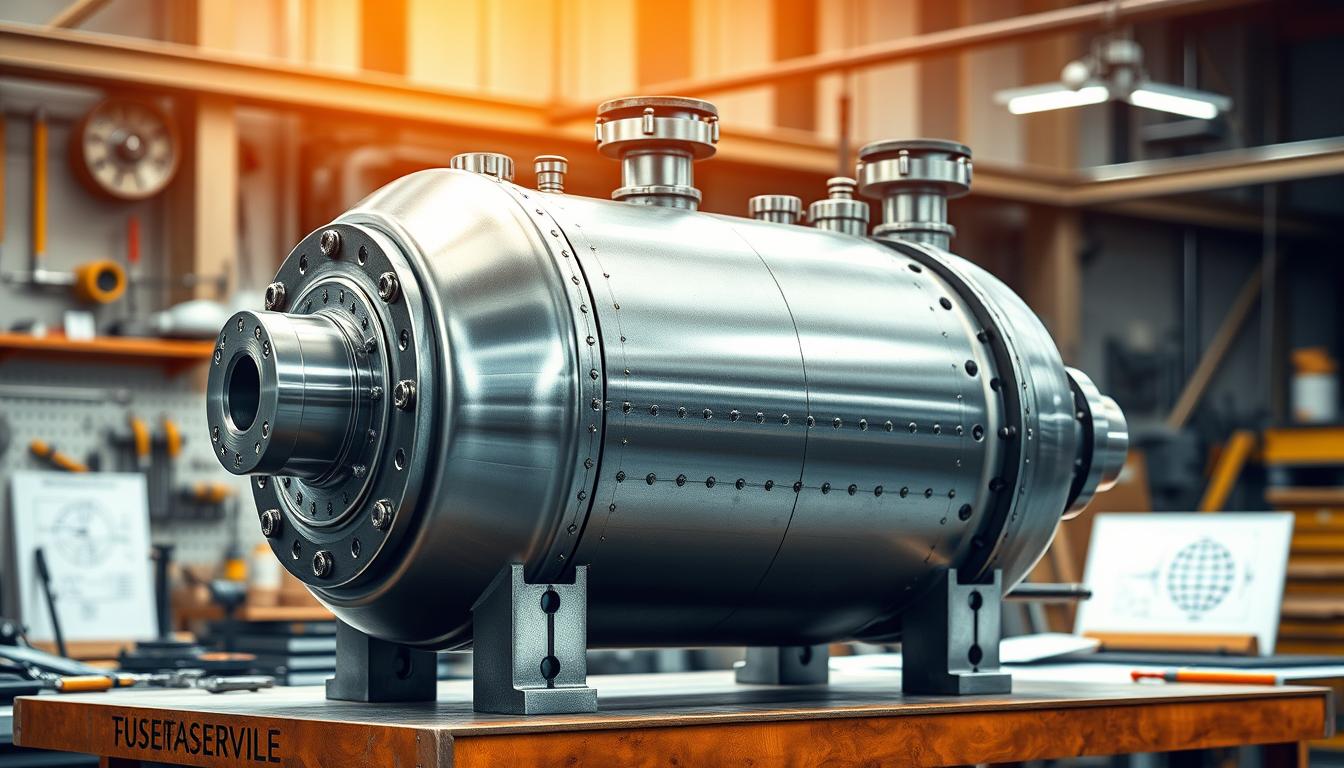

A pressure vessel holds gases or liquids under high pressure. You’ll find them in many forms, like cylindrical and spherical shapes. They’re used for storing steam, compressed gases, and more.

Bad design can lead to big problems. Vessels might burst, causing fires or toxic leaks. Past accidents at refineries and chemical plants show the dangers. That’s why making vessels safe is so important.

In the U.S., rules and standards guide how vessels are made. The ASME Boiler and Pressure Vessel Code (BPVC) Section VIII is key. API standards and OSHA rules also play a part in making sure vessels are safe.

I aim to share the basics with you. This includes how to design vessels, choose materials, and ensure they’re built right. This guide is for engineers, managers, and anyone working with high-pressure vessels. It’s all about keeping things safe and running smoothly.

Overview of Pressure vessels in engineering design:

I give a quick look at pressure vessels in engineering. It shows how design fits into plant engineering. It connects process design, piping, and more to ensure everyone knows what’s needed early on.

I explain what goes into designing a vessel. This includes design pressure and temperature, how long it will last, and if it will be used a lot or just occasionally. It also looks at if it will be exposed to corrosion or wear, and any loads it might face. Plus, it considers the environment it will be in.

Next, I talk about the shape and setup of the vessel. You can choose between a cylinder or a sphere, and whether it will be standing up or lying down. The type of ends it has also matters, affecting how it’s built and how it holds up.

I cover the engineering aspects that guide these choices. Things like how stress is spread out, where welds can be accessed, and where it can be inspected or lifted. These factors impact cost and safety. Using computer simulations early on can help avoid costly changes later.

I then discuss what the vessel needs to do. This includes how much pressure it can handle, the lowest temperature it can work in, and how safe it needs to be. It also looks at how it will handle changes in temperature and how often it will start and stop.

I explain how to plan for connections and access. Where nozzles and manways go, how it will be supported, and if it needs insulation or a protective coating. It also considers space for maintenance and how it fits with the piping and instruments.

I describe the first steps in a project. This includes making data sheets, picking materials, and doing initial sizing. Working closely with both process engineers and mechanical designers at this stage can save a lot of trouble and money later on.

Fundamental principles of pressure vessel design:

I start with the basic stresses in shells. For thin-walled cylinders, I use formulas for hoop and longitudinal stress. I explain when membrane stress is more important than bending.

I mention the thin-wall limit as t/R ≤ 0.1. I also talk about when thick-wall solutions are needed.

I discuss stress analysis methods for sizing and reinforcement. I explain how membrane and bending stress combine near openings. I also mention how local stress increases at nozzles and weld toes.

I refer to ASME Section VIII for shell and head thickness calculations. These calculations account for stress intensification.

I describe common failure modes engineers must watch out for. Yielding and plastic collapse set basic strength limits. External pressure collapse or buckling is a concern in vacuum or sub-atmospheric service.

Brittle fracture is a big worry at low temperatures. Fatigue drives failure under cyclic loads. Creep is a concern at high temperatures.

I explain how design margins and allowable stresses are set. Allowable limits come from yield or tensile values with temperature-dependent factors. Codes use these margins to keep service stresses safe.

I mention how corrosion allowance adds to required thickness. This helps maintain margins over time.

I summarize fracture mechanics basics to prevent brittle fracture. I define fracture toughness (K_IC) and the difference between crack initiation and propagation. I explain how Charpy V-Notch impact testing and radiographic requirements inform material selection and inspection.

I explain fatigue design techniques I use. I use S‑N curves with material and weld detail categories. I apply cumulative damage using Miner’s rule and include stress concentration factors.

I reduce stress ranges through geometry changes and control weld quality. This lowers fatigue risk.

I finish by stressing inspection-oriented design choices. I build in corrosion allowance or select corrosion-resistant alloys and linings when needed. I design access for ultrasonic, radiographic, and visual inspection at critical zones.

This keeps the pressure vessel fundamentals aligned with safe, serviceable designs.

Calculations and methodologies for safe design:

I explain how I size shells, heads, and nozzles by hand. I use ASME formulas to find the minimum thickness needed. This includes adding a corrosion allowance for extra safety.

I list the important load cases for every project. First, I check internal and external pressures. Then, I look at wind, seismic, nozzle, and thermal loads. I also consider hydrostatic test pressure and combined loads.

I talk about how I get the data for stamping and nameplates. The MAWP, design temperature, material, and code stamp come from my calculations. These details are key for certification and getting the vessel ready for use.

I discuss stress classification in ASME and its impact on design. I separate stresses into primary, secondary, and tertiary. This helps me decide when to check for fatigue. It keeps the design safe and follows the code.

I explain when to use modern tools for complex designs. For nozzles and supports, I use FEA to find local stress. Nonlinear analyses help with buckling and plasticity when needed.

I share tips for using finite element analysis. I check mesh sensitivity, use realistic conditions, and compare with hand calculations. This ensures the FEA results are reliable for design.

I cover how I handle thickness and corrosion allowance. I base the corrosion allowance on expected rates and inspection plans. I also document test procedures and safety steps according to ASME.

I stress the importance of documenting calculations and getting peer review. Each project has detailed calculation sheets and a load case matrix. For critical vessels, I get a third-party review to meet all standards.

Materials, fabrication, and welding practices:

I choose pressure vessel materials based on several factors. These include yield and tensile strength, toughness, and chemical compatibility. I also consider temperature limits and cost. For general service, I often use carbon steel, like A516 Grade 70 for its strength and economy.

When dealing with corrosive or high-temperature streams, I prefer stainless steel, such as 304 or 316. For situations requiring resistance to creep or chemicals, I opt for alloy steels or nickel alloys.

I always require mill certificates and traceability for my purchases. I list ASTM and ASME SA designations on requisitions. For low-temperature toughness, I request tensile, hardness, and Charpy impact tests.

Heat treatment records are essential for inspection and longevity. I document any post-manufacture furnace cycles.

Welding procedures are key to safe fabrication. I use qualified welding procedures and PQRs that match base metals and consumables. Welders must be qualified according to ASME Section IX.

For thicker sections and materials prone to hydrogen cracking, I mandate preheat and interpass temperature control. Stress relief through PWHT is specified to temper weld zones and reduce residual stress.

I plan weld sequence and clamping to limit distortion and control residual stresses. Certified welding consumables with traceable lot numbers are required.

Fabrication quality control is critical. I enforce jigs and fixtures for alignment and measure critical dimensions continuously. I require RT or UT for critical welds and use PT or MT for surface-breaking defects.

I set NDE acceptance criteria to match the governing code and service risk. I document all NDE results and retain reports with the job package. Factory acceptance testing and witnessing key examinations are conducted before shipping.

Surface protection and coatings are vital for long-term performance. I specify primers, epoxy, or polyurethane topcoats for external protection. Internal linings like rubber, glass-flake, or epoxy are used when process fluids demand it.

I design insulation and details to minimize corrosion under insulation. Materials that resist trapped moisture are selected. Shop practices influence final quality. I require controlled welding environments, disciplined fit-up, and proper tack patterns.

I verify dimensional tolerances, check for distortion, and perform corrective machining when needed. I document fabrication steps to maintain traceability from raw plate to finished vessel.

My approach balances material selection, welding procedures, PWHT where needed, and disciplined fabrication. This reduces risk, extends service life, and aligns the build with code requirements and client expectations.

Inspection, testing, and maintenance strategies:

I start with pre-commissioning tests to ensure long-term safety. A hydrostatic test is common, with pressures up to 1.5 times the design pressure. Safety is a top priority during these tests.

When liquid tests are risky, pneumatic tests are used with strict rules. Leak tests and gauge calibration are done before starting up.

I talk about NDT methods and their uses. Radiography (RT) is great for checking welds inside. Ultrasonic testing (UT) measures wall thickness and checks welds.

Magnetic particle (MT) and dye penetrant (PT) find surface defects. New tools like phased-array UT and time-of-flight diffraction help find cracks better and with less error.

I explain how in-service inspection programs work in the U.S. API 510 guides inspections and repairs in many plants. The frequency of inspections depends on several factors like risk and operating conditions.

Clear records are key for repairs and changes. This meets audit and regulatory needs.

I discuss monitoring corrosion and thickness to guide maintenance. Baseline thickness maps and repeated surveys track corrosion. Corrosion coupons, probes, and guided wave ultrasonics are used for long-range checks.

Predictive maintenance is about reducing downtime. It uses vibration monitoring, acoustic emission, and infrared thermography. Combining corrosion and inspection plans into a reliability program makes maintenance more effective.

I talk about repair practices and code compliance after defects are found. Authorized repairs follow ASME and API rules and may need requalification. Keeping detailed records is essential for clear responsibilities and assessments.

Safety, regulatory compliance, and design optimization:

I explain the rules for keeping pressure vessels safe in the U.S. We look at ASME BPVC Section VIII Divisions 1 and 2 and API standards like API 650 and API 620. These rules are key for storage and process vessels.

OSHA’s process safety management rules also play a big role. They affect how vessels are designed and run. This is why design acceptance, code stamping, and third-party checks are so important.

I talk about how to follow these rules from the start of design to getting certified. It’s all about having the right documents and following what third parties say. This leads to code stamping.

I also cover what records to keep and audits to show you’re following the rules. These steps help keep vessels safe over time.

I then get into how to assess and lower risks. We use HAZOP and LOPA to spot risks and figure out what could happen if a vessel fails. We also talk about how to prevent overpressure and use engineering controls.

These steps help make sure incidents are less likely and less severe. It’s all about keeping vessels safe.

In the end, I talk about making vessels better and lasting longer. We look at how to balance cost and safety, and how to make vessels stronger without adding too much weight. We also talk about using new materials and testing methods to keep vessels safe for longer.