Dry gas mechanical seals are key in many industrial settings. They work differently than old seals that use fluids. Instead, they use gas to stop leaks.

This new technology cuts down on contamination risks. It also makes equipment last longer. Choosing the right dry gas mechanical seal is vital for top performance and saving on upkeep.

Understanding Dry Gas Mechanical Seals:

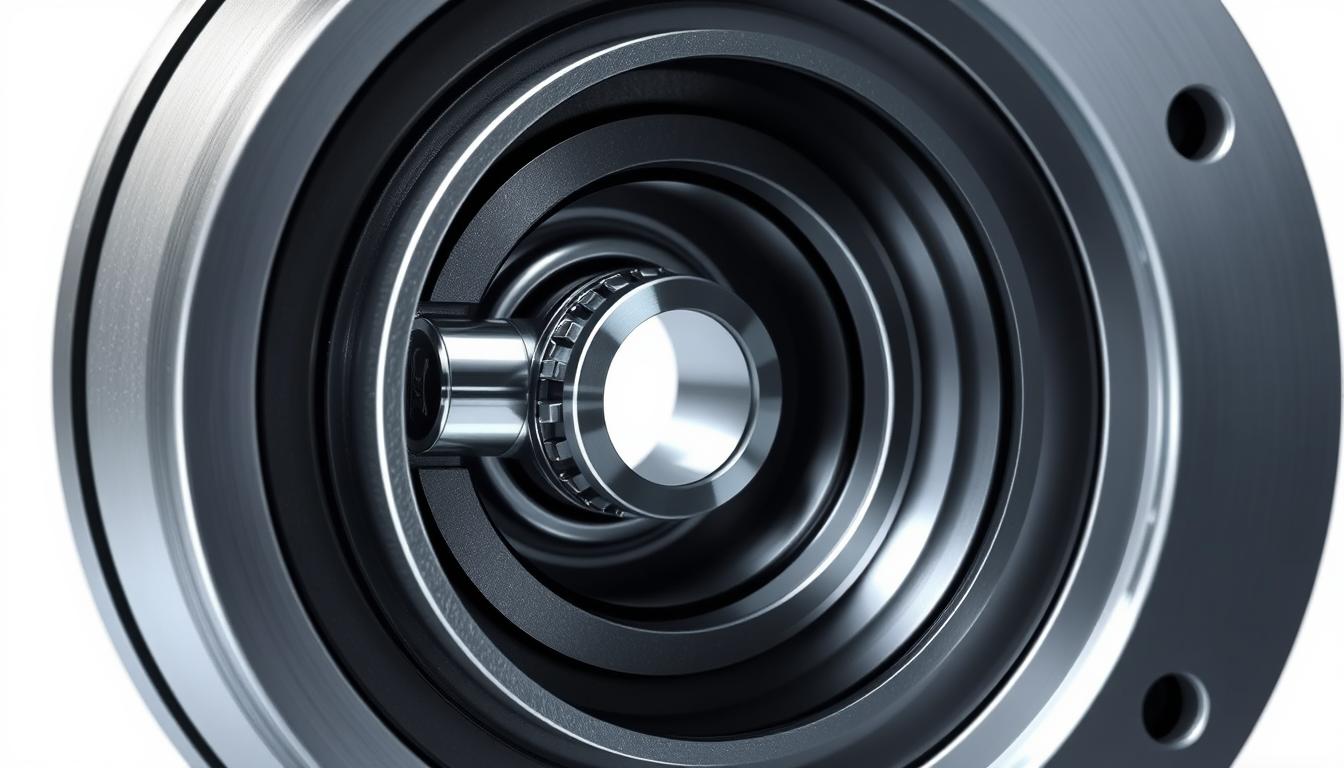

Dry gas mechanical seals are key in sealing technology. They have a special design that makes them stand out. The seals have a rotating and a stationary part that work together to stop gas leaks.

This design is vital in places with high pressure and temperature, like compressors and turboexpanders.

The way dry gas seals work is quite innovative. They seal without needing oil, which means they last longer and work better. This is important for keeping them running well in many situations.

Knowing about dry gas seals helps us pick the best seal for different needs. It’s all about finding the right fit for each job.

Dry gas seals are very important in many fields. They help keep gas in place with great accuracy. Thanks to these seals, industries can work more efficiently.

Advantages of Dry Gas Mechanical Seals:

Dry gas seals offer many benefits over traditional sealing methods. They work without lubrication, which means less maintenance and longer seal life. This is a big plus for me, as it means my equipment needs less upkeep.

These seals also protect the environment by preventing gas leaks. This makes my operations safer and more eco-friendly. It’s good to know I can run my business efficiently and responsibly.

Cost savings are another big plus. Dry gas seals mean less time and money lost to repairs. This helps me keep my business running smoothly and avoid unexpected costs. Research by groups like the American Society of Mechanical Engineers shows these seals can save a lot of energy.

Mechanical Seals: How They Work:

Understanding how mechanical seals work is key to seeing their value. These seals have parts like sealing faces and springs. They work together to keep a tight seal, even when things move or vibrate.

The dry gas seal mechanism is really interesting. It uses a thin layer of gas to prevent the faces from touching. This method reduces wear and makes the seal last longer. Different materials, like carbon and ceramic, are used based on what’s needed.

Applications of Dry Gas Mechanical Seals:

Dry gas mechanical seals are key in many fields, like oil and gas, chemical processing, and power generation. They work best in centrifugal and reciprocating compressors. These seals keep systems safe in tough gas environments.

Many companies rely on these seals for safety and better performance. They help keep operations running smoothly.

In petrochemical plants, using compressor seals is critical to avoid gas leaks. Dry gas mechanical seals are reliable in stopping leaks. This keeps people and equipment safe and boosts process efficiency.

Looking at case studies, it’s clear that using mechanical seals helps a lot. Industries see better performance, less downtime, and lower maintenance costs. Choosing the right seals is vital for each specific need.

Maintenance and Troubleshooting Tips for Mechanical Seals:

Keeping dry gas mechanical seals in good shape is key to their long life and performance. I suggest setting up a regular check-up schedule. This helps spot wear, misalignment, and corrosion early on. Catching these issues early can save a lot of time and money later.

When you’re dealing with mechanical seals, it’s important to know the common problems. These include leaks and unusual vibrations. I use a methodical approach to find these issues. By watching how the equipment works and using vibration analysis, I can catch problems before they get worse.

Getting advice from experts in the field is also very helpful. They know the best ways to take care of mechanical seals for different machines. Their advice helps me keep my equipment running smoothly and efficiently.