In the world of work, knowing how to keep electrical motors running well is key. This guide will teach you how to fix electrical motors quickly. This way, you can avoid long breaks and keep things running smoothly.

Regular checks and care for your motors can make them last longer. It also saves money in the long run. Let’s look at some important ways to keep your motors in top shape.

Understanding the Basics of Electrical Motors:

Electrical motors change electrical energy into mechanical energy. This happens through electromagnetic induction. When I study motor operation, I learn about key factors like torque and speed.

The stator and rotor are essential in this process. They help the motor work efficiently and perform well.

Exploring different electrical motor types helps me understand more. Each type is made for certain uses and has special features. Knowing standards like NEMA and IE is important when picking a motor. This knowledge helps me keep motors running well and fix problems.

Common Types of Electrical Motors:

Knowing the different types of electrical motors is key when choosing the right one for various tasks. AC motors are very popular because they are efficient and versatile. They come in two main types: synchronous and induction motors.

Synchronous motors always run at the same speed, no matter the load. This makes them perfect for certain industrial jobs. Induction motors, on the other hand, are found in many household items and machines. They are strong and easy to use.

DC motors are important for tasks that need speed control. They can change speed by adjusting the voltage, which is useful in many situations. I’ve used DC motors a lot in robotics and automation because they offer great control.

Stepper and servo motors are also important for specific tasks. Stepper motors give precise control over movement, which is great for 3D printers and CNC machines. Servo motors are known for their ability to position accurately, making them perfect for robotics.

Importance of Regular Electrical Motor Maintenance:

Knowing how important motor maintenance is is key for anyone using electrical motors. Keeping these motors in good shape means they last longer and work better. If you ignore this, you might face more damage, unexpected shutdowns, and safety risks.

Regular maintenance brings big benefits. It helps motors run more efficiently, which saves money. Studies show that well-kept motors can last up to 50% longer than neglected ones. This shows why it’s smart to keep up with maintenance to avoid breakdowns and extend your equipment’s life.

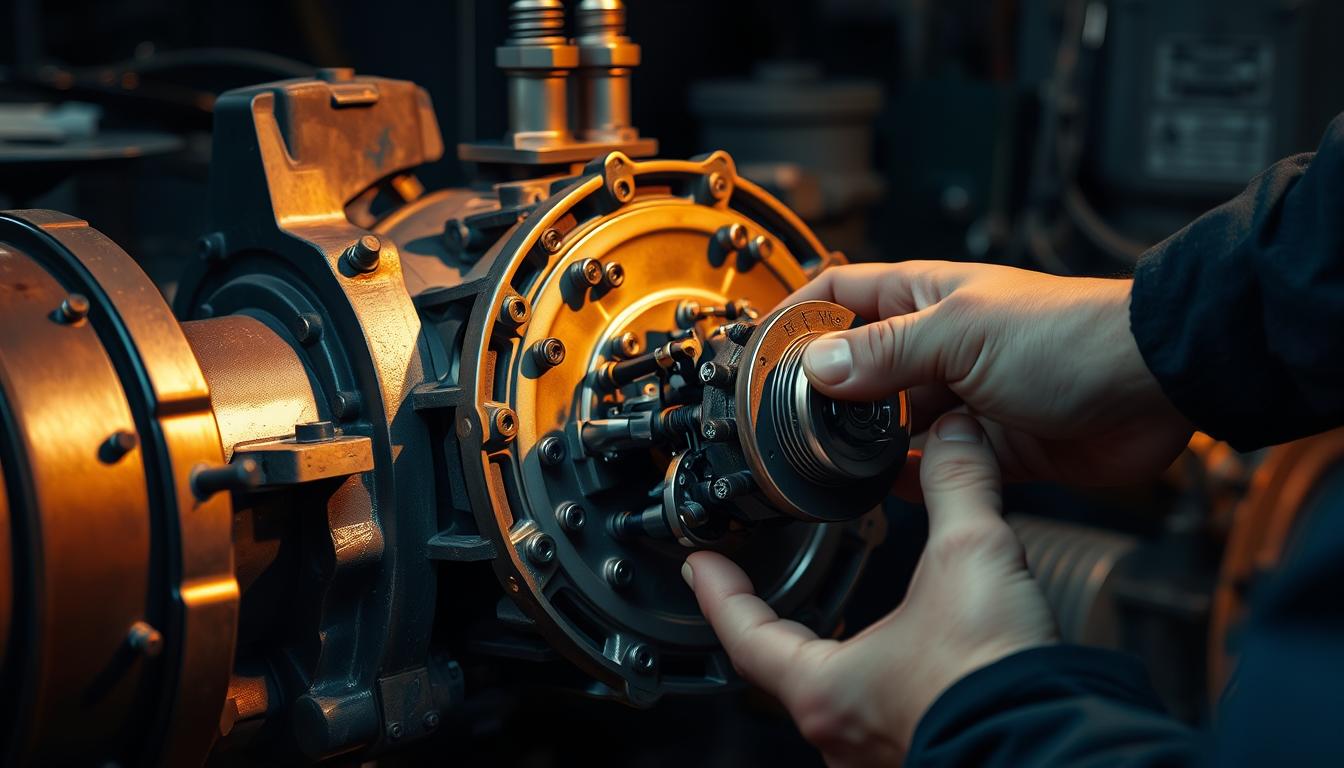

Key Components of an Electrical Motor:

An electrical motor has several key parts that work together well. Knowing how these parts fit together is key for fixing problems and keeping them running right. The main parts are the stator, rotor, windings, bearings, and casing. Each one is important for the motor’s success.

The stator is the motor’s fixed part. It holds the windings that make a magnetic field when electricity flows. This field works with the rotor, the moving part, to create mechanical energy. Keeping these parts in good shape helps the motor work better and last longer.

Bearings help the rotor spin smoothly. If they wear out, the motor can lose efficiency. The casing protects the motor’s inside from the outside world. Knowing how these parts work together helps me spot problems and do better maintenance.

Electrical Motor Maintenance Best Practices:

Maintaining electrical motors is key to their long life and good performance. I stress the need for regular checks. These inspections help find problems early, so we can fix them quickly.

Keeping bearings lubricated is a must to reduce friction and wear. This simple action boosts efficiency and stops overheating. It’s also important to clean the motor to avoid electrical failures. I suggest dusting and checking both inside and outside parts often.

Checking electrical connections is vital for the motor to work right. Bad connections can cause power loss and harm. Adding temperature checks to our routine helps spot overheating, a sign of a problem. These steps help keep our equipment in top shape.

Keeping detailed maintenance logs is also important. Recording performance and inspection results helps track the motor’s health. It also shows patterns that might need more attention. With these practices, our motors work better and last longer.

Diagnosing Electrical Motor Issues:

When I start diagnosing motor problems, I look for common signs like overheating, unusual noises, or drops in performance. These symptoms can help me find the main cause of the issue. For example, too much heat might mean the motor is overloaded or not cooling enough. Strange sounds could point to mechanical problems or failing bearings.

Fixing electrical motor troubles is key to keeping it running well and lasting longer. I often use vibration analysis to spot imbalances or misalignments in the motor parts. This method shows me how the motor is doing and helps avoid big problems from small ones.

Thermal imaging is also a big help in my work. It lets me see heat patterns in the motor without touching it. This shows me where hotspots are, which can mean electrical issues or insulation problems. Knowing these signs helps me fix problems fast, so the motor works right and efficiently.

Tools Needed for Electrical Motor Maintenance:

Effective electrical motor maintenance depends on the right tools. I always use multimeters to measure voltage, current, and resistance. These measurements help me find and fix motor problems.

A torque wrench is another key tool. It ensures the right amount of torque on fasteners, avoiding damage. Insulation resistance testers check motor windings’ condition, helping prevent failures.

Having a well-stocked toolkit for electrical motors makes maintenance easier. A good toolkit includes lubricants to reduce friction. High-quality tools save time and ensure better work.

Using tools safely is essential. Always follow the manufacturer’s instructions and practice safety. This way, we avoid injuries and protect the equipment. The right tools and safety practices lead to effective maintenance and motor longevity.

Safety Tips When Handling Electrical Motors:

Keeping safe around electrical motors is key to avoiding accidents. I always follow safe handling practices. Before starting any maintenance, I make sure the motor is turned off. This step greatly reduces the risk.

Wearing the right protective gear is also vital. I use insulated gloves and safety goggles to protect myself. This helps prevent injuries from unexpected events.

Lockout/tagout (LOTO) procedures add extra safety. They make sure power sources are cut off until work is done. Keeping my workspace tidy is another way to stay safe. A clean area helps avoid accidents.

I’m also ready for emergencies with a clear plan. Knowing where circuit breakers are and having first aid kits nearby is part of my safety plan. By doing these things, I help make our work area safer for everyone.

When to Call in a Professional for Electrical Motor Issues:

Dealing with electrical motor problems can be easy or hard, depending on the situation. Knowing when to call a pro is key to fixing issues right. If I face complex electrical failures, it’s time to get an electrician to keep things safe and working well.

Structural damage to the motor needs special tools and skills I might not have. In such cases, getting help from an expert is the best way to fix it. I think carefully about whether I should try to fix it myself or call a certified technician.

When I see signs of wear or malfunction but am unsure, I think about my experience. I ask myself if trying to fix it could make things worse. This careful thinking helps me make smart choices, keeping safety and efficiency in mind.

Resources for Further Learning on Electrical Motors:

To learn more about electrical motors, I look for various resources. I start with specific manuals from companies like Siemens and ABB. These manuals give detailed information on their models and how to maintain and fix them.

Industry publications like “Electrical Apparatus” and “Electrical Engineering” also help. They share the latest in electrical motor technology. These resources are great for both new and experienced technicians, keeping me up-to-date with the best methods and new trends.

Online platforms with learning materials for electricians are also key. Sites with courses from places like the National Electrical Contractors Association (NECA) are very helpful. They offer everything from basic to advanced knowledge. Using these resources, I can grow my skills and solve motor maintenance and troubleshooting problems better.