In the world of thermal engineering, knowing how engineering flow and heat exchangers work together is key. Heat exchangers are critical for moving energy efficiently, which is important for many industries. Their design affects both flow and energy use, making them central to thermal management.

Understanding the Basics of Thermal Engineering:

Exploring thermal engineering, I see it’s key to understand heat transfer and thermodynamics. Heat transfer happens through conduction, convection, and radiation. Each method is important in different ways.

Conduction lets heat move through materials. Convection helps heat move in fluids. Radiation is special because it lets heat travel through empty space.

Knowing these basics helps me see how heat exchangers work. It also makes me appreciate energy systems more. By learning these core ideas, I can handle thermal energy better in many areas. This includes both industrial and home heating systems.

The Importance of Flow Dynamics in Heat Transfer:

In my studies of thermal engineering, I’ve learned how vital flow dynamics is for better heat transfer. Knowing about fluid mechanics, like viscosity and turbulence, helps improve heat exchanger performance. For example, turbulent flow boosts heat transfer by mixing and dissipating energy more.

Managing flow dynamics well leads to better heat transfer coefficients. These coefficients are key to reducing energy loss in systems. By studying flow rates, I can find the best conditions for performance. This knowledge helps in creating more efficient heating and cooling systems and advances thermal technology.

Heat Exchanger: Types and Applications:

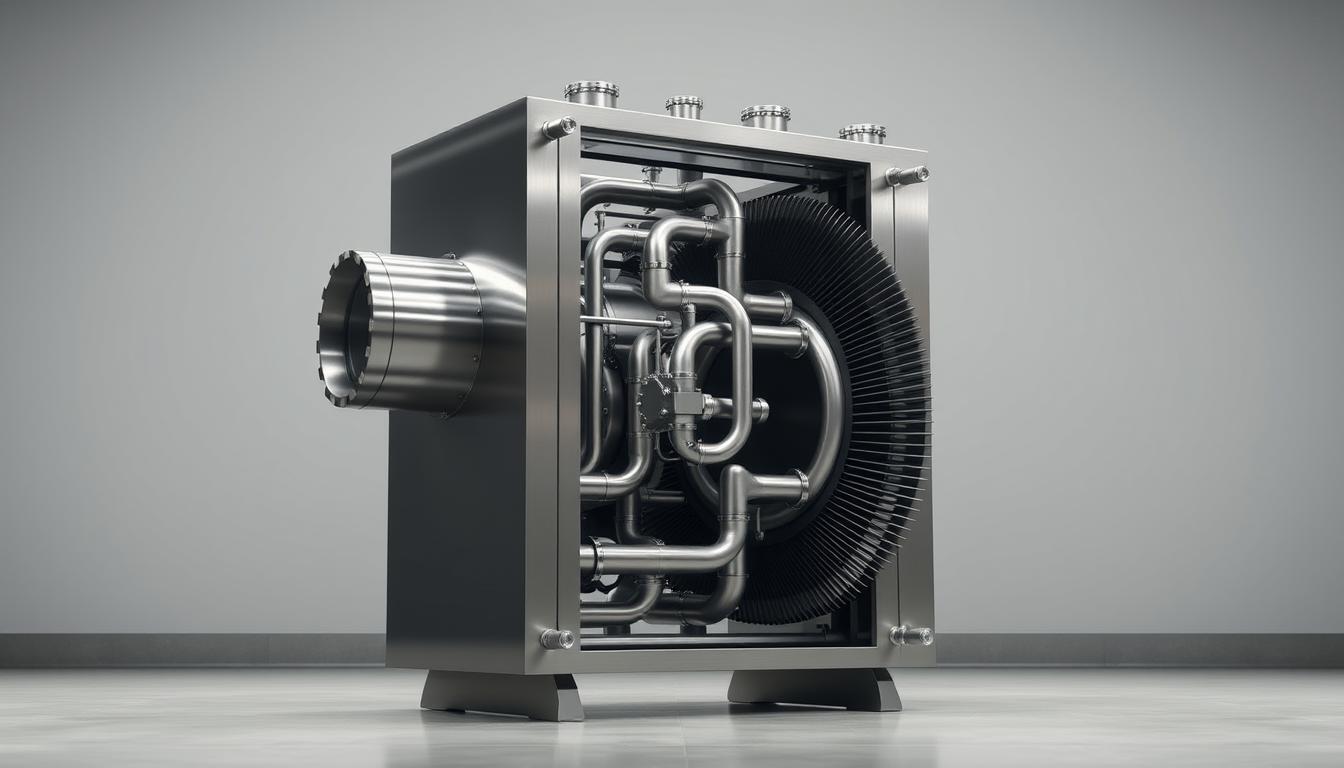

Exploring heat exchangers, I see it’s key to know the different types. This includes shell and tube and plate heat exchangers. Each type has its own role in various industries, bringing unique benefits to specific tasks. Shell and tube exchangers are a hit in the petrochemical world because they can handle tough conditions.

On the other hand, plate heat exchangers are gaining ground in HVAC systems. They’re loved for their small size and top-notch heat transfer skills.

There are also finned tube and air-cooled exchangers for special tasks in food and chemical making. When picking a heat exchanger, I look at things like temperature, fluid type, and space. These details affect how well the exchanger works. Knowing about these heat exchangers helps me make better choices on the job.

How to Optimize Heat Exchanger Efficiency:

Optimizing heat exchanger efficiency requires a multi-step approach. Regular maintenance is essential to keep systems running smoothly. It helps prevent downtime and ensures peak performance.

Preventative maintenance is a big part of this. It lets me fix small issues before they become big problems. This way, efficiency stays high.

Design improvements are also important. I increase heat transfer surfaces and adjust flow rates to boost performance. Using advanced materials with better thermal conductivity helps too.

Each improvement leads to a better temperature difference. This maximizes energy performance.

Monitoring system performance with data analytics is another key strategy. It helps me spot trends and anomalies early. This proactive approach boosts efficiency and extends equipment life.

By combining maintenance, design improvements, and monitoring, I achieve optimal heat exchanger efficiency. It’s all about keeping systems running at their best.

Innovations in Heat Exchanger Technology:

Recent advancements in heat exchanger technology have changed the thermal engineering world. I’ve seen exciting changes that focus on smaller designs and better materials. These improvements boost performance and reliability.

Smart sensors are now part of these systems for real-time monitoring. They allow for quick adjustments, making processes more efficient.

New materials like enhanced alloys and composites are also being used. They make systems more durable and better at handling heat. The goal is to use less energy while producing more.

As industries face tighter rules and environmental targets, heat exchangers play a key role. They help meet these challenges by improving efficiency and performance.

Common Challenges in Heat Exchanger Design:

In my work with heat exchanger design, I’ve seen many common problems. One big issue is thermal stress. This happens when materials face big temperature changes, leading to wear and tear.

Fouling is another big problem. It’s when unwanted stuff builds up on the heat transfer surfaces. This not only makes the heat exchanger less efficient but also adds to the thermal stress. It’s important to pick the right materials and maintain them well to avoid these issues.

Designing for different fluids is also a challenge. Each fluid reacts differently to temperature changes. To overcome this, I need to understand fluid dynamics and heat transfer well. This helps me create heat exchangers that work better and last longer.

Future Trends in Heat Exchange Systems:

Looking ahead, sustainability and energy efficiency will lead the way in heat exchanger trends. Engineers are working on new materials and designs. These aim to improve thermal performance and cut down on environmental harm.

This is key in HVAC, power generation, and process manufacturing. Better efficiency means big energy savings and less carbon emissions.

Emerging tech like AI and IoT is changing heat exchange systems. AI helps analyze data in real-time for better maintenance and optimization. IoT devices make monitoring and control smarter, ensuring peak performance under different conditions.

Working with renewable energy is becoming more important. Heat exchangers will soon work with solar thermal systems and biomass. This mix of new tech and green practices is not just a trend; it’s a must.

For me, it’s about more than following rules. It’s about leading in saving resources and energy. Heat exchangers are key to our sustainable future.