Hydraulic lifts are used in many places, from auto repair shops to construction sites. Hydraulic lifts make moving large objects quick and easy. But did you know you can also build a simple and user-friendly small hydraulic lift yourself? Whether you’re interested in engineering or just want to learn more about basic mechanics, this DIY guide will help you build a small hydraulic lift that works well. Let’s talk about how to build your own small hydraulic lift, the materials you’ll need, and some helpful tips.

What does a hydraulic lift do?

Hydraulic lifts use the force of fluids to move objects. The basic principle of hydraulic lifts stems from Pascal’s law, which states that when you apply pressure to a fluid, the fluid spreads evenly in all directions. In short, hydraulic lifts can easily move large objects. This is the main reason why they are so effective for jobs that require moving heavy objects easily.

Materials Needed

- You’ll need a few simple items to build your own small hydraulic lift. For this project, you’ll need the following supplies:

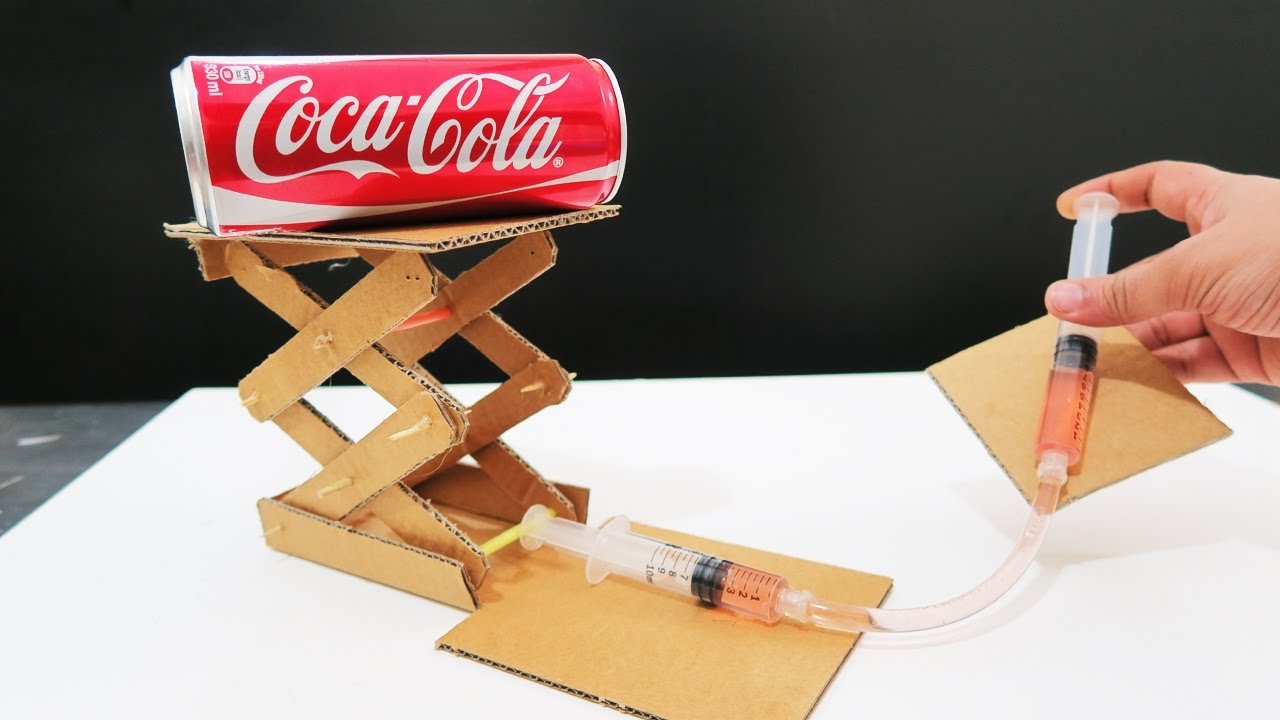

- Lift pump: A small hydraulic jack or syringe is used as a lift pump.

- Sheet steel or wooden base: Used to create the base and the lifting platform.

- Hydraulic oil: Used to fill the mechanism and evacuate air.

- The lifting arm is made from steel rods or tubing.

- Nuts, bolts, and screws: Used to assemble the frame.

- Pressure hose: Used to connect the hydraulic jack to the lifting arm.

- Used to cut metal rods and plates.

- Drill: Used to drill holes for the nuts and bolts.

- (Optional) Welder: If you’re using metal to create the frame, you’ll need to join them together.

- Once you have all the parts ready, you can start building your small hydraulic lift.

Building a small hydraulic lift step by step

1. Prepare the base

First, build the base of the hydraulic lift. The entire system is stably supported by this base. The base can be made of sheet steel or sturdy wood. The base must be large enough for the hydraulic jack and leave room for the lifting platform.

2. Assemble the lifting platform

Next, build the platform to be moved. The platform can be a small wooden or metal platform to place the object on. The base must be connected to the hydraulic arm, which in turn is connected to the hydraulic jack. Use steel rods or steel tubing to make the lifting arm. Ensure the arm is long enough to reach the desired lifting height.

3. Install the hydraulic jack

The most important part of the lifting system is the hydraulic jack. Install the hydraulic jack at one end of the base to ensure proper operation. To raise and lower the platform, the jack must pump hydraulic oil through the system. Ensure the jack is properly connected so it doesn’t move while the lifting system is operating.

4. Connect the hydraulic hoses

The hydraulic jack must be connected to the lift arm with an air hose. This hose transports pressurized hydraulic oil from one location to another. When the jack is moved, hydraulic oil flows through the air hose. This activates the lift arm and raises the platform.

5. Injecting hydraulic oil into the system

Hydraulic lifts require hydraulic oil to operate. Inject the correct type of hydraulic oil into the hydraulic jack. This is very important to apply pressure to the lift arm and allow it to move. To prevent leaks or problems, always follow the manufacturer’s recommendations regarding the amount of hydraulic oil to use.

6. Checking the system

Test the lift before using it. Ensure that the lifting platform moves evenly and smoothly. If there is resistance or weak links, check the system for leaks or ensure that the hoses and hydraulic supports are properly connected.

7. Adding the Finishing Touches

Once the lift is fully operational, you can put the finishing touches on the structure. Give the frame a more professional look by painting it and add any safety features, such as safety bars or a way to lock the platform during use.

8. Hydraulic Lift Comparison Chart

Here’s a quick overview of some common types of hydraulic lifts you might consider building, depending on your needs:

| Feature | Mini Hydraulic Lift | Full-Scale Hydraulic Lift | Air Hydraulic Lift |

|---|---|---|---|

| Lifting Capacity | Up to 500 kg | Up to 10 tons | Varies (usually lower) |

| Speed of Lifting | Moderate | Slow | Fast |

| Size and Portability | Compact | Bulky | Portable |

| Maintenance | Low | High | Low |

| Cost | Affordable | Expensive | Moderate |

Tips for Enhancing Your DIY Hydraulic Lift

Use high-quality materials: The materials you use will determine the lifespan of your small hydraulic lift. Purchase a sturdy metal frame and high-quality hydraulic fluid to ensure smooth operation.

Take care during assembly: Be careful when assembling your lift. Measure carefully and ensure all parts are properly tightened to prevent damage or movement.

Regular maintenance: Small hydraulic lifts, just like full-size hydraulic systems, require regular inspection. Check that the hydraulic fluid is sufficient and look for signs of wear.

Question 1: What is the lifting capacity of a small hydraulic lift?

In most cases, a small hydraulic lift can lift up to 1,100 pounds (500 kg). Of course, the actual lifting capacity can also vary depending on the size of the hydraulic jack and the material the lift is made of.

Question 2: Can I use a small hydraulic lift to repair my car?

Yes, a small hydraulic lift can be used for small vehicles or simple lifting tasks, such as car repairs or maintenance. But for larger vehicles, it’s best to use a professional hydraulic lift.

Question 3: How do I prevent leaks in my hydraulic system?

To prevent leaks, ensure all connections are tight and that the hydraulic lines are properly connected to the lift arms and jacks. Regularly check for signs of fluid leakage and repair worn seals.

Question 4: Can I use this lift to move furniture?

A small hydraulic lift is ideal for moving or renovations, as it’s easy to move large furniture. Make sure the platform is large enough to accommodate the furniture.

Question 5: Is it difficult to build a small hydraulic lift?

Building a small hydraulic lift isn’t difficult, but you do need some basic technical and hydraulic knowledge. Anyone with basic DIY skills and the right tools and supplies can do the job.

Summary

Building a small hydraulic lift is a fun and practical DIY project that teaches you a basic understanding of hydraulic and mechanical systems. With just a few simple materials, tools, and time, you can create a lift that works and is versatile. A small hydraulic lift can easily move everything from small cars to large furniture. Just make sure the lift is in good working order and follow safety regulations to ensure safe operation.