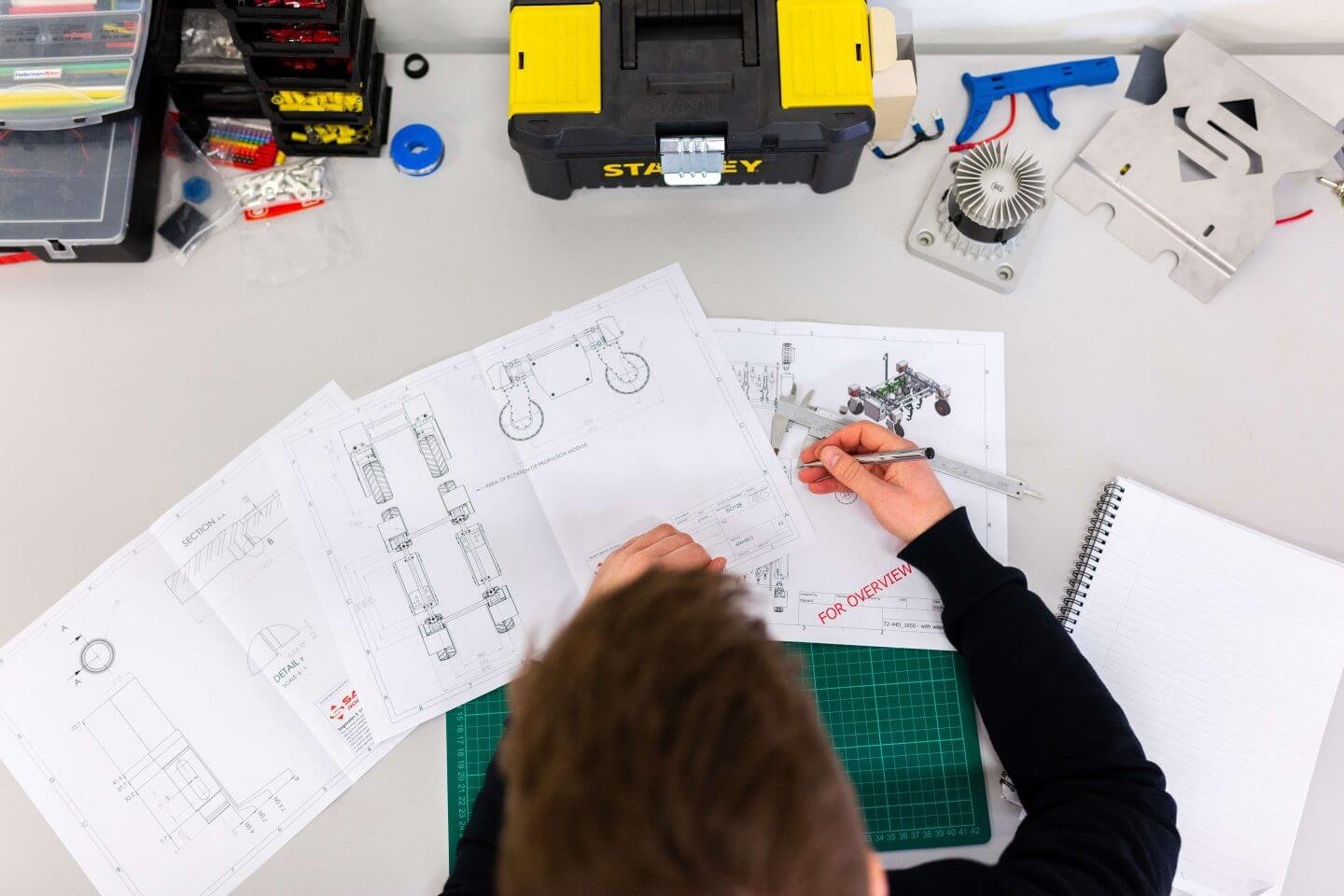

An important part of engineering is mechanical design, which is the process of making and improving mechanical systems and parts to meet specific useful needs. If you want to make sure your product is efficient, reliable, and cost-effective, whether you’re creating a simple machine, a complicated system, or something that will be mass-produced, you need to know the basic rules and best practices of mechanical design.

This piece will talk about the basic ideas behind mechanical design and give engineers and designers tips on how to make the best designs that are also new and high-quality.

What does mechanical design mean?

The use of engineering concepts to create mechanical systems and parts is what mechanical design is all about. It includes taking an idea or need and turning it into a thorough plan that can be built, tried, and made. A lot of different things go into mechanical design, such as basic design, thorough design, analysis, development, and testing.

Automotive, aircraft, industrial machinery, consumer goods, robots, and medical devices are just a few of the engineering fields that use mechanical design. The goal is to make ideas that work, are safe, last a long time, don’t cost too much, and meet all the performance and standard requirements.

1. Function and Purpose

The first step in any mechanical design process is to figure out how the product works. What problem does the product solve? This is one of the most important things designers need to ask. What are the design’s most important parts and needs? It should be clear what the design is meant to do because that will help with choosing the right materials, size, shape, and function.

2. Choosing the Material

Picking the right materials is very important for the success of a design. Materials need to be picked out based on things like

- Strength and Durability: Making sure the material can handle the pressures and forces it will face while it is being used.

- Cost: The prices of materials can have a big effect on the project’s total budget.

- Weight: Many times, it’s important to keep the weight as low as possible, especially in aircraft and automobile designs.

- Corrosion Resistance: This is an important thing to think about when choosing materials for goods that will be used in tough settings so that they last a long time.

To choose the right material, you need to know about its qualities, like its tensile strength, wear limit, and heat conductivity, and how they affect the performance of the design.

3. Making things easy and quick

When designing something mechanical, one important rule is to keep it as simple as possible while still meeting the needs of function. A simpler form is usually:

- makes making things easier and cheaper.

- Has fewer parts, which lowers the chance that it will break.

- is more dependable and less difficult to keep up.

Trying to keep things simple doesn’t mean giving up efficiency. The goal of efficient designs is to get the job done with the fewest parts and the least amount of complexity.

4. Making things uniform

Standard parts should be used as much as possible in mechanical designs. This includes parts that are easy to find and have known qualities, like screws, bearings, bolts, and gears. Setting standards for parts cuts down on design time and production costs while making sure that they work with each other and are easy to put together.

5. Design to Make It Easy to Make (DFM)

Making sure the product can be made at a reasonable cost and with little trouble requires careful planning during the design process. When designing something with DFM, you have to think about how it will be made. For example:

- Keeping complicated cutting methods to a minimum.

- If it’s not totally necessary, avoid tight limits.

- Making parts that are simple to put together and take apart.

Using DFM concepts can help cut down on mistakes, avoid extra work, and lower overall production costs.

6. Ergonomics and Psychology of Work

Ergonomics and human factors must be thought about for things that people will touch, like tools, medical devices, and market goods. This means making goods that are simple and safe to use so that people are less likely to hurt themselves or strain themselves. Important things to think about are:

- The size, shape, and weight of the product.

- How to use it and where to put the controls.

- Safety and ease of entry.

7. Checking and tests

Testing is an important part of mechanical design because it makes sure the product meets all the standards and works as planned in the real world. Different kinds of tests can be done, such as:

Making a sample to check the idea and do actual tests is called prototyping.

Stress testing means looking at how the product works when it’s under a lot of stress, such as checking for tiredness and failure.

natural testing means putting the product through different kinds of natural situations, like high or low temperatures, high or low humidity, or exposure to chemicals.

Testing both makes sure that the system works and finds any problems with the design that need to be fixed.

The best ways to design machines

1. Make sure your needs are clear

You should be sure you understand the problem you are trying to solve before you start the planning process. Get all the facts you need, such as:

- Needs and hopes of the customer.

- Specifications for performance.

- Regulatory rules or guidelines for the business.

- Limitations on budget and time.

Making sure the design stays on track and meets all the requirements is easier if the requirements are clear.

2. Use Computer-Aided Design (CAD) software to make models

CAD software is an important part of current mechanical design. CAD software lets engineers make 3D models of products so they can see what they will look like and quickly change the designs. It also comes with testing and modelling tools that can help find problems with the design before a sample is made.

These CAD tools are often used for machine design:

- 3D SolidWorks

- AutoCAD

- Blender 360

- PTC Creo

Not only does CAD software speed up the design process, it also makes it easier for teams to work together by letting them share and work on ideas from different places.

3. Do a thorough analysis

If you design a product without doing enough research, it might not work in the real world. To make sure the design can stand up to the situations it will be put through, engineers should use modelling tools to do a thorough analysis. Some common methods of analysis are:

- FEA is a computer program that models how parts will react to loads, deformations, and forces.

- Computer-aided fluid dynamics (CFD) is a way to look at how fluids move and heat moves through systems like HVAC or car designs.

- When systems have moving parts, like robots or tools, motion simulation is used.

- These research tools give useful information that helps improve the plan before it is made.

4. Design Process With Iterations

The design process should be fluid, which means that engineers should try, tweak, and improve the design all the time. Don’t try to make the first version perfect. Instead, start with an idea, make a prototype, and then test it and get feedback to make small changes that make the prototype better.

Iterative design helps keep risks under control and makes sure that the end product works and can be made.

5. Working together and talking to each other

A lot of the time, mechanical designers work with groups of professionals from different fields, like makers, electrical engineers, and material scientists. Working together and talking to each other well are important for making sure that all the parts of the plan fit together well.

To keep everyone on the same page throughout the project, there must be regular meetings, clear paperwork, and sharing of design files.

In conclusion

Mechanical design is a difficult but interesting area that needs a strong grasp of engineering ideas and best practices. Engineers can make designs that work well, last a long time, and don’t cost too much by focussing on usefulness, ease, material choice, and the ability to make the design. Using current tools like CAD software and modelling tools can also speed up the design process, which can lead to better results and a shorter time to market.

These rules and methods will help you do well in the world of mechanical design, no matter if you are a student just starting out in mechanical engineering or a seasoned professional.