In the world of modern engineering, machine design engineering is key. It combines creativity with technical skills. This field is vital for making machinery and equipment that work well in many industries.

These include the automotive, aerospace, and manufacturing sectors. As I explore design engineering, I’ll show how important it is to balance looks and function. Good design makes systems work better and more efficiently.

Bad design can really hurt how well things work. It’s important to understand these engineering principles. This knowledge helps us create better solutions and innovate.

Understanding Machine Design Engineering:

Machine design engineering is all about understanding the basics of engineering. It starts with knowing what the project needs. Then, choosing the right materials is key. These materials must meet the project’s needs and follow technical rules.

Computer-Aided Design (CAD) is a big help in this field. It lets me make detailed designs and test them virtually. This way, I can make sure my designs work well before I build them. Following industry standards helps me create solutions that are both new and meet all the rules.

The Importance of Design Engineering:

Design engineering is very important. It plays a key role in many industries. It makes things work better, safer, and cheaper.

Design engineers think about what people need and what’s popular. This way, they create solutions that are not just good but also stand out.

Design engineering has a big impact on industries. It helps them change quickly, work more efficiently, and meet customer needs. For example, in cars and planes, good design means better performance and reliability.

This shows why we need to keep innovating. It’s not just good; it’s necessary for success.

As technology gets better, so does engineering. Design engineering makes companies more adaptable. This is key in a competitive world.

Companies that get this can lead in their field. They also help the environment. Design engineering is key to progress and change.

Key Principles of Machine Design:

Working in machine design engineering, I’ve learned that knowing the basics is key. It’s all about forces, material properties, and understanding how things move and work. These principles help make sure our designs work well and last long.

Also, thinking about how reliable and affordable a design is matters a lot. I aim to make machines safe and easy to use. Before we make many, we test prototypes. This helps us see if our design works as planned.

Innovative Technologies in Machine Design:

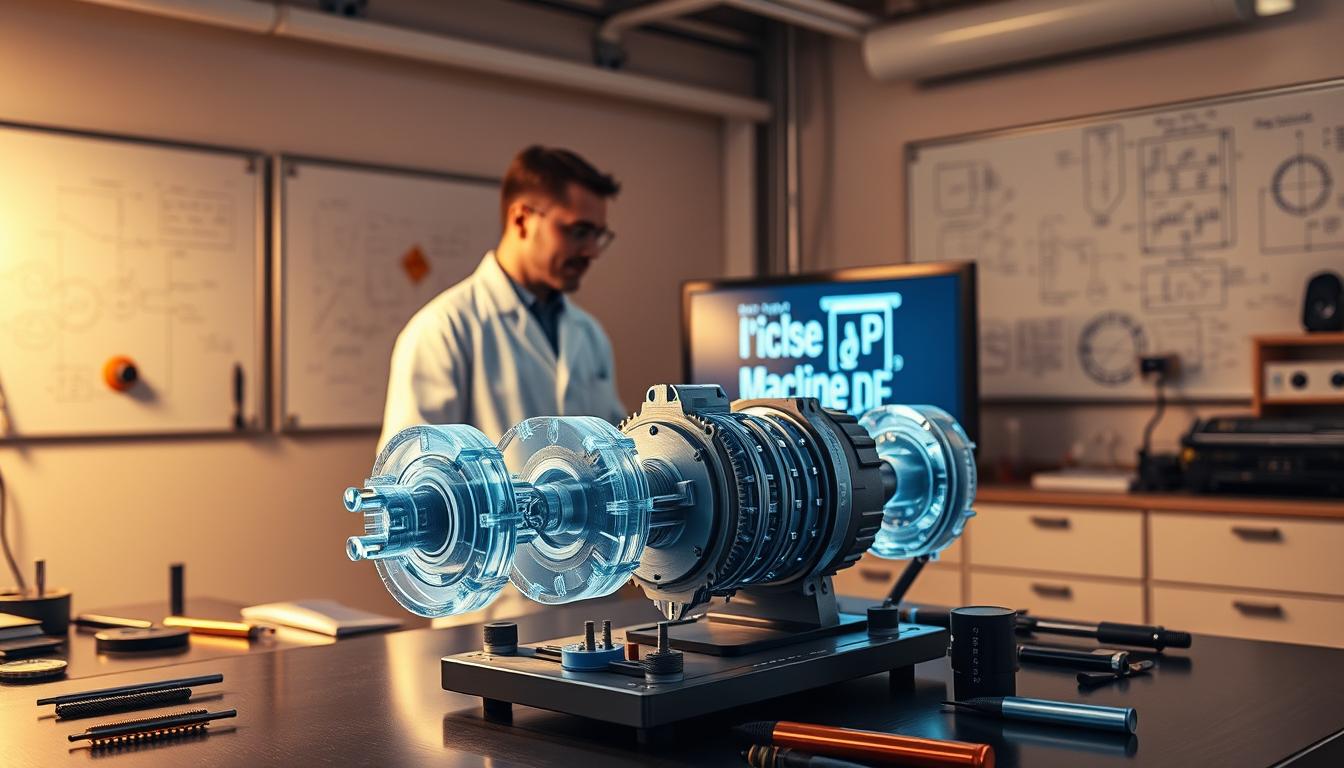

The world of machine design engineering is changing fast. New technologies are making designs more efficient and creative. CAD advancements let designers make detailed models and simulations. These tools give instant feedback and help make changes quickly.

3D printing in engineering is also a big change. It makes it easy to create prototypes and parts that were hard to make before. This means engineers can try out designs and test ideas faster.

Smart machinery and automation are also key. They make production more precise and cut down on mistakes. By using artificial intelligence, I can make designs better and predict problems before they happen.

With CAD systems and 3D printing, we have a strong base for future innovations. This setup helps us create, change, and make things faster. It supports my goal of efficient design engineering that meets today’s industry needs.

Applications of Machine Design Engineering:

Machine design engineering is used in many fields. It’s amazing to see how design principles are applied in car making, electronics, and machinery. For example, Ford and General Motors use new design methods to make cars better and safer. This leads to solutions that meet what people need today.

Companies like Apple and Samsung use machine design to make products that look good and work well. They focus on making things easy for users. This is key to keeping their place in the market.

Industrial machinery also benefits from machine design engineering. Caterpillar, for instance, uses advanced designs to make heavy equipment more efficient and reliable. The goal is to improve performance while keeping costs down. By looking at these examples, we can see how design leads to better manufacturing.

Sustainability in Machine Design:

With growing environmental worries, making machines sustainable is key. Choosing eco-friendly materials is a big step. It helps reduce harm to the planet during production.

Energy use is also important. I aim to make machines that use less power. This helps us move towards a greener future. It also fits with the circular economy, where we reuse and recycle more.

But, making machines sustainable is hard. It’s tough to pick green options without sacrificing performance. Laws and standards also play a big part in pushing for green design.

Challenges in Machine Design Engineering:

The world of machine design engineering is full of challenges. Technological limits often slow down the creative process. Engineers struggle with old tools or materials that don’t meet today’s project needs.

Keeping up with new technology is key for solving design problems. Adapting to new software, methods, or materials is hard but necessary for success.

Budget limits are another big challenge. Designers must work within tight budgets to create quality designs. This requires creative thinking and making tough choices about where to spend money.

Delivering on time and keeping quality high is critical in a competitive market. Managing resources well is essential to overcome these challenges.

Feedback is very important. Using feedback to improve designs is a key part of the process. Working with others and learning from feedback helps overcome obstacles.

Looking ahead, the need for ongoing learning and flexibility will be vital. These traits will help designers face the challenges of machine design engineering.