Mechanical Design: A Complete Guide to Principles and Practice

Mechanical design forms the backbone of every product we use, from the smartphone in your pocket to the car you drive. This engineering discipline combines creativity with technical precision to solve real-world problems through the development of mechanical systems, components, and devices.

Whether you’re an aspiring engineer, a student exploring career paths, or a professional looking to deepen your understanding, this comprehensive guide covers everything you need to know about mechanical design. You’ll discover the fundamental principles that govern this field, explore the design process from concept to completion, and learn about the cutting-edge tools and technologies shaping the future of mechanical engineering.

Mechanical design isn’t just about creating functional products—it’s about optimizing performance, ensuring safety, and balancing multiple competing requirements to deliver solutions that improve our daily lives. Let’s explore how mechanical designers transform ideas into the machines and mechanisms that power our modern world.

What is Mechanical Design?

Mechanical design is the process of creating mechanical systems, components, and devices that perform specific functions while meeting various requirements such as performance, safety, cost, and manufacturability. This multidisciplinary field combines engineering principles with creative problem-solving to develop everything from simple tools to complex machinery.

At its core, mechanical design involves understanding how forces, motion, materials, and energy interact within a system. Designers must consider factors like stress distribution, thermal effects, vibrations, and wear patterns to ensure their creations function reliably over their intended lifespan.

The scope of mechanical design extends across numerous industries, including automotive, aerospace, consumer products, medical devices, robotics, and manufacturing equipment. Each application brings unique challenges that require specialized knowledge and innovative approaches.

Fundamentals of Mechanical Design

Material Selection and Properties

Understanding material properties is crucial for successful mechanical design. Engineers must consider factors such as strength, stiffness, density, thermal conductivity, and corrosion resistance when selecting materials for specific applications.

Common materials in mechanical design include:

- Metals: Steel, aluminum, titanium, and their alloys offer excellent strength-to-weight ratios and proven reliability

- Polymers: Plastics provide versatility, corrosion resistance, and cost-effectiveness for many applications

- Composites: Carbon fiber and fiberglass composites deliver exceptional performance in demanding environments

- Ceramics: Advanced ceramics offer superior wear resistance and high-temperature performance

Stress Analysis and Load Distribution

Mechanical components must withstand various types of loads throughout their operational life. Understanding how forces distribute through a structure enables designers to optimize material usage while ensuring safety margins are maintained.

Key stress types include:

- Tensile stress (pulling forces)

- Compressive stress (pushing forces)

- Shear stress (parallel forces)

- Torsional stress (twisting forces)

- Fatigue stress (repeated loading cycles)

Kinematics and Dynamics

The study of motion—both with and without considering the forces that cause it—is fundamental to mechanical design. Kinematics focuses on describing motion, while dynamics examines the relationship between forces and motion.

These principles are essential when designing:

- Linkage mechanisms

- Gear systems

- Cam and follower arrangements

- Robotic joints and actuators

Key Principles and Considerations

Design for Manufacturing (DFM)

Successful mechanical design must consider manufacturing constraints from the earliest stages. DFM principles help ensure that products can be produced efficiently, cost-effectively, and with consistent quality.

Important DFM considerations include:

- Selecting appropriate manufacturing processes

- Minimizing complex geometries that are difficult to produce

- Standardizing fasteners and components

- Designing for automated assembly when possible

Safety and Reliability

Mechanical designers bear significant responsibility for user safety and product reliability. This involves implementing multiple layers of protection and conducting thorough risk assessments.

Safety considerations encompass:

- Fail-safe design principles

- Emergency shutdown systems

- Protective guards and barriers

- Warning systems and user interfaces

Sustainability and Environmental Impact

Modern mechanical design increasingly emphasizes sustainability throughout a product’s lifecycle. This includes material selection, energy efficiency during operation, and end-of-life disposal or recycling considerations.

Sustainable design strategies include:

- Using recycled or renewable materials

- Designing for disassembly and recycling

- Optimizing energy efficiency

- Minimizing waste during manufacturing

Common Mechanical Design Elements

Fasteners and Joints

Mechanical assemblies rely on various fastening methods to connect components securely. Understanding the strengths and limitations of different joint types is essential for reliable design.

Threaded Fasteners: Bolts, screws, and nuts provide removable connections with high strength capacity. Thread selection depends on load requirements, environmental conditions, and assembly constraints.

Welded Joints: Permanent connections offering excellent strength but requiring skilled labor and quality control measures.

Adhesive Bonding: Chemical fastening methods that distribute loads over large areas and can join dissimilar materials effectively.

Bearings and Bushings

Supporting rotating or sliding components requires careful bearing selection to minimize friction, wear, and maintenance requirements.

Rolling Element Bearings: Ball and roller bearings provide low friction and long service life for rotating applications.

Plain Bearings: Simple, cost-effective solutions for lower-speed applications or where space constraints limit rolling element bearing use.

Magnetic Bearings: Advanced contactless bearing systems offering ultra-low friction and maintenance-free operation for specialized applications.

Springs and Dampers

Energy storage and vibration control elements play crucial roles in many mechanical systems.

Compression Springs: Store energy when compressed and return it when released, commonly used in suspension systems and mechanisms.

Tension Springs: Work in the opposite manner, storing energy when stretched.

Torsion Springs: Provide rotational force and are essential components in many mechanical devices.

The Mechanical Design Process

Requirements Definition

Every successful design project begins with clearly defined requirements that establish what the system must accomplish. This phase involves extensive stakeholder consultation and market research to understand user needs, performance expectations, and constraints.

Requirements typically include:

- Functional specifications

- Performance parameters

- Environmental conditions

- Safety standards

- Cost targets

- Schedule constraints

Conceptual Design

During this creative phase, designers generate multiple solution concepts and evaluate their feasibility. Brainstorming sessions, sketching, and preliminary calculations help identify promising approaches.

Effective conceptual design involves:

- Exploring multiple solution paths

- Considering unconventional approaches

- Evaluating concepts against requirements

- Selecting the most promising designs for further development

Detailed Design and Analysis

Selected concepts undergo rigorous analysis and refinement during detailed design. This phase involves precise calculations, computer simulations, and iterative optimization to ensure performance requirements are met.

Key activities include:

- Creating detailed drawings and specifications

- Conducting finite element analysis

- Performing tolerance studies

- Optimizing for cost and performance

Prototyping and Testing

Physical prototypes validate design assumptions and reveal issues that may not be apparent in theoretical analysis. Testing protocols should comprehensively evaluate performance under expected operating conditions.

Prototyping strategies range from:

- Rapid prototyping for quick concept validation

- Functional prototypes for performance testing

- Pre-production prototypes for manufacturing validation

Tools and Technologies Used in Mechanical Design

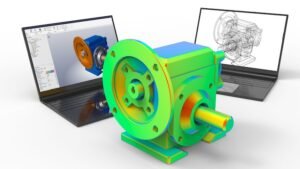

Computer-Aided Design (CAD) Software

Modern mechanical design relies heavily on sophisticated CAD software that enables precise 3D modeling, assembly simulation, and automated drawing generation.

Leading CAD platforms include:

- SolidWorks: Widely used in mechanical engineering for its user-friendly interface and robust feature set

- Autodesk Inventor: Comprehensive solution with strong simulation capabilities

- CATIA: High-end platform favored in aerospace and automotive industries

- Fusion 360: Cloud-based solution integrating design, simulation, and manufacturing tools

Finite Element Analysis (FEA)

FEA software enables designers to simulate complex loading conditions and predict component behavior before physical testing. This technology significantly reduces development time and costs while improving design reliability.

Popular FEA tools include:

- ANSYS

- Abaqus

- SolidWorks Simulation

- Nastran

Computational Fluid Dynamics (CFD)

For designs involving fluid flow, heat transfer, or aerodynamics, CFD analysis provides crucial insights into system behavior. These tools simulate complex fluid interactions that would be difficult or impossible to analyze analytically.

Emerging Trends in Mechanical Design

Additive Manufacturing Integration

3D printing technology is revolutionizing mechanical design by enabling complex geometries that were previously impossible to manufacture. Designers can now create internal channels, lattice structures, and integrated assemblies that optimize performance while reducing part count.

Benefits of additive manufacturing include:

- Design freedom for complex geometries

- Rapid prototyping capabilities

- Mass customization opportunities

- Reduced assembly requirements

Smart Materials and Adaptive Systems

Shape memory alloys, piezoelectric materials, and other smart materials enable mechanical systems that adapt to changing conditions automatically. These technologies open new possibilities for self-adjusting mechanisms and responsive structures.

Digital Twin Technology

Digital twins create virtual replicas of physical systems that update in real-time based on sensor data. This technology enables predictive maintenance, performance optimization, and design validation throughout a product’s lifecycle.

Sustainable Design Focus

Environmental consciousness is driving innovation in materials science, energy efficiency, and circular economy principles. Mechanical designers increasingly prioritize sustainability metrics alongside traditional performance measures.

Real-World Applications: Case Studies

Automotive Suspension System

Modern vehicle suspension systems demonstrate the complexity of mechanical design in balancing comfort, handling, safety, and durability. Engineers must optimize spring rates, damping characteristics, and geometric relationships while considering manufacturing constraints and cost targets.

Key design challenges include:

- Managing conflicting requirements for comfort and performance

- Ensuring safety under extreme conditions

- Minimizing noise, vibration, and harshness

- Achieving target weight and cost objectives

Medical Device Design

Mechanical design in medical applications requires exceptional attention to safety, biocompatibility, and regulatory compliance. Surgical instruments, prosthetics, and diagnostic equipment must function reliably in challenging environments while meeting strict quality standards.

Design considerations include:

- Material biocompatibility

- Sterilization requirements

- Ergonomic factors for medical professionals

- Patient safety and comfort

Aerospace Applications

The aerospace industry pushes mechanical design to its limits with extreme performance requirements, weight constraints, and safety standards. Every component must demonstrate exceptional reliability while minimizing mass and maintenance requirements.

Critical factors include:

- Extreme temperature and pressure conditions

- Vibration and shock resistance

- Weight optimization

- Long-term reliability without maintenance access

Taking Your Next Steps in Mechanical Design

The field of mechanical design offers countless opportunities for innovation and problem-solving across diverse industries. Success requires a solid foundation in engineering principles combined with creativity, attention to detail, and continuous learning.

For those entering the field, focus on developing strong analytical skills while gaining hands-on experience with modern design tools. Understanding manufacturing processes, material properties, and industry standards provides the practical knowledge essential for effective design work.

Experienced professionals should stay current with emerging technologies like additive manufacturing, smart materials, and digital simulation tools. These advances continue to expand the possibilities for innovative mechanical solutions.

The future of mechanical design lies in the integration of traditional engineering principles with cutting-edge technologies, sustainable practices, and user-centered design approaches. By mastering these fundamentals while embracing new tools and methodologies, mechanical designers will continue to create the products and systems that shape our world.

Frequently Asked Questions

What educational background is needed for mechanical design?

Most mechanical design positions require a bachelor’s degree in mechanical engineering or a related field. Some roles may accept associate degrees or technical certifications combined with relevant experience. Advanced positions often prefer candidates with master’s degrees or specialized training in specific industries.

How important is computer skills in modern mechanical design?

Computer skills are essential in contemporary mechanical design. Proficiency with CAD software, simulation tools, and data analysis programs is typically required. Most employers expect familiarity with industry-standard software packages and the ability to learn new tools as technology evolves.

What industries offer the best opportunities for mechanical designers?

Mechanical design opportunities exist across numerous industries, including automotive, aerospace, consumer products, medical devices, energy systems, and manufacturing equipment. The best opportunities often depend on regional industry concentrations and individual interests and expertise.

How do mechanical designers stay current with industry developments?

Successful mechanical designers maintain their knowledge through professional development activities such as continuing education courses, industry conferences, technical publications, and professional organization memberships. Many also pursue advanced certifications or specialized training in emerging technologies.

What is the typical career progression for mechanical designers?

Career paths typically progress from entry-level design positions to senior designer roles, then to lead engineer or project management positions. Some designers specialize in specific technical areas, while others move into management, consulting, or entrepreneurship roles.

References

Professional development in mechanical design benefits from consulting authoritative sources including:

- American Society of Mechanical Engineers (ASME) standards and publications

- Engineering textbooks on machine design, materials science, and manufacturing processes

- Industry-specific design guides and best practices

- Peer-reviewed journals focusing on mechanical engineering and design

- Software vendor documentation and training materials for CAD and simulation tools