Working with centrifugal pumps, I know how vital a good guide is. This article is here to help you learn the basics and more. It’s all about making sure your pumps work well and stay safe.

From the first steps of understanding how they work to keeping them in top shape, we’ve got you covered. We’ll also look at what’s coming next in pump technology. This guide is for everyone, whether you’re just starting or have years of experience.

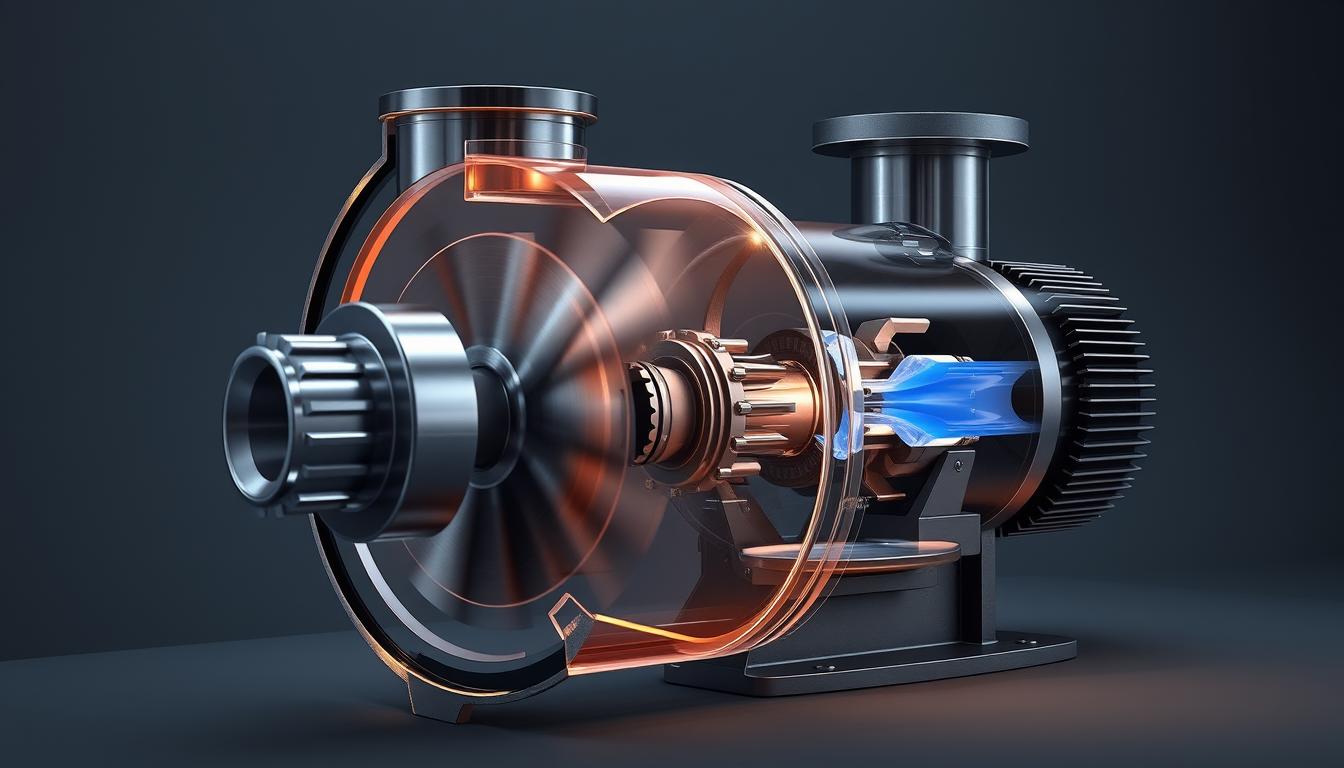

Understanding the Basics of Centrifugal Pumps:

My exploration of centrifugal pump basics started with learning their key mechanics. These pumps use centrifugal force to move fluids efficiently. Watching the impeller spin shows how it works. It creates a low-pressure area at its center, pulling fluid in.

After the fluid enters, the pump’s design takes over. The impeller pushes the fluid out through the casing. This moves the liquid from the intake to the discharge side. Knowing the parts like the impeller and casing is key. It helps me fix problems and keep the pump running well.

Types of Centrifugal Pumps:

Centrifugal pumps are key in many industries. Knowing the different types is vital for their proper use. The single-stage pump works well for low-pressure tasks, giving reliable results in simple setups.

For higher pressures, the multi-stage pump is the best choice. It handles big pressure increases and elevation changes, making it flexible for many needs.

The submersible pump is special because it works underwater. It’s perfect for pulling water from the ground or managing waste. The self-priming pump is great for tasks needing automatic priming. It’s easy to set up and stays efficient under changing conditions.

Knowing about these pumps helps me pick the right one for each job. This ensures they work their best. Understanding these differences highlights their role in moving liquids efficiently.

Applications of Centrifugal Pumps:

Centrifugal pumps are used in many industries. They are great at moving fluids in places like processing plants and chemical factories. They also work well in cooling systems, helping to keep things running smoothly.

In agriculture, these pumps are key for irrigation and drainage. They help manage water, which is vital during growing seasons. The right pump can make sure water is used well, helping crops grow and saving water.

For municipal water systems, pumps are essential. They help supply water, manage waste, and treat sewage. Pumps are important for keeping our water clean and safe. Their design makes them reliable in different settings.

Choosing the Right Centrifugal Pump:

Choosing the right centrifugal pump is a big decision. It involves looking at several important criteria. The flow rate is key, as it shows how well the pump can move fluid. Each job has its own needs, so it’s important to consider things like head requirements and what kind of fluid it is.

Other important factors include the fluid’s viscosity, temperature, and if it can handle chemicals. If you ignore these, your pump might not last long. This can cause a lot of downtime and cost a lot of money. It’s smart to check the manufacturer’s specs and follow industry standards when picking a pump.

Operating Procedures for Centrifugal Pumps:

It’s vital to follow the right steps when operating centrifugal pumps. This ensures they work well and last longer. Before starting, I check for leaks and make sure the pump is primed. I also set all controls to the right levels for the best performance.

While the pump is running, I watch for signs like temperature, vibration, and flow rates. This helps catch problems early. When it’s time to stop, I let the pump cool down and drain it completely. This keeps it safe for the next use.

Maintenance Tips for Centrifugal Pumps:

Regular maintenance of centrifugal pumps is key to keeping them running well and lasting longer. I stress the need for a preventive maintenance plan. This plan should include regular checks and oiling of moving parts.

During these checks, I look for wear on seals and damage to impellers. This helps catch problems early.

Checking vibration levels and using thermal imaging are also smart moves. These steps help spot issues before they get worse. Keeping records of maintenance helps track performance and plan for repairs.

Efficiency and Performance Optimization:

Improving centrifugal pumps is key to better efficiency and saving energy. Knowing the pump curve is very helpful. It shows how flow rate and head are connected. Choosing pumps that work at their best efficiency point (BEP) greatly improves performance and cuts down energy use.

Using variable frequency drives (VFDs) is another smart move. They let me adjust pump speed as needed. This not only saves energy but also helps control the process better. By doing these things, I can make my system work better and save money too.

Safety Considerations When Operating Centrifugal Pumps:

Being aware of hazards is key when working with pumps. Centrifugal pumps can have mechanical failures, electrical risks, and handle dangerous fluids. Following OSHA and NFPA safety standards is vital. These rules help keep operations safe and reduce risks.

Wearing the right personal protective equipment (PPE) is important. I always wear gloves, goggles, and protective clothes. Keeping the work area clean and organized also helps prevent accidents and boosts efficiency.

Training is essential for pump safety. Everyone working with pumps should get proper safety training. This teaches them how to handle hazards and respond quickly. Regular safety drills keep safety top of mind in daily work.

Future Trends in Centrifugal Pump Technology:

Centrifugal pump technology is changing fast, making pumps more efficient and green. Smart sensors and IoT are now common in advanced pumps. They let us watch performance in real-time and adjust automatically for better results.

Predictive maintenance is also key in pump tech’s future. It uses data to spot problems early, cutting downtime and costs. This approach helps save energy and supports sustainability goals.

The materials in pumps are getting better too. They’re now more durable and resistant to corrosion. This means pumps last longer and work better, helping us keep our systems efficient and eco-friendly.