Pump cavitation is a big problem that can hurt the performance and life of industrial pumps. It happens when the pressure in the pump changes quickly, creating vapor bubbles. These bubbles then burst, causing damage to the pump parts.

It’s important to know about pump cavitation, whether you work in water treatment, oil and gas, or chemical processing. Spotting cavitation issues early helps keep pumps running smoothly. This saves time and money by avoiding expensive repairs.

What is Pump Cavitation?

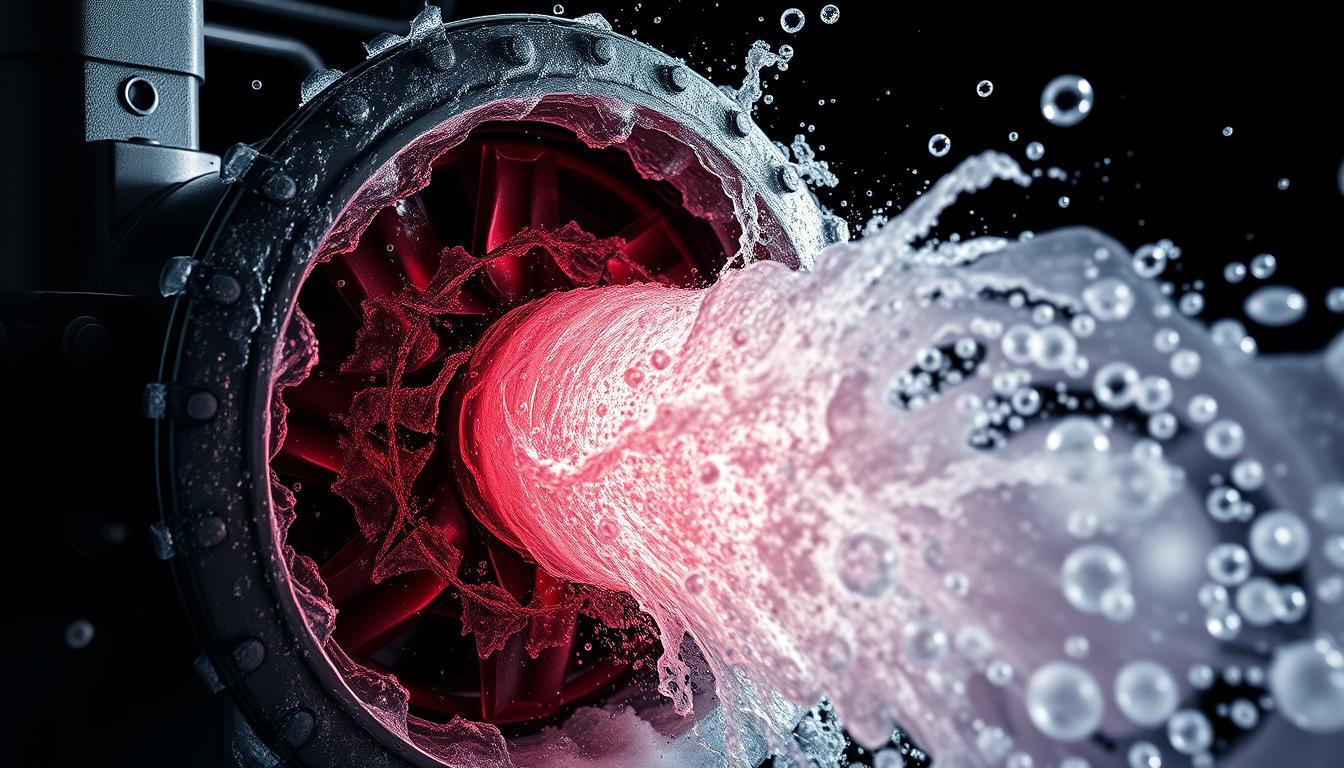

Pump cavitation is a phenomenon in fluid dynamics, mainly seen in centrifugal pumps. It happens when there are low-pressure zones in the fluid flow. These zones can cause vapor bubbles to form.

When the pressure changes suddenly, these bubbles collapse violently. This can cause a lot of damage to the pump.

Knowing why cavitation happens is key to keeping pumps working well. High flow speeds can create low-pressure areas, making pumps more likely to cavitate. Also, a pump that’s too small can lead to inefficiencies and more pressure changes, which help bubbles form.

Changes in temperature can also affect the fluid’s vapor pressure. This can contribute to cavitation.

Identifying Pump Cavitation Symptoms:

It’s important to spot the signs of pump cavitation to keep pumping systems running well. A common sign is pump noise, like grinding or rattling sounds. These sounds usually mean there are pressure changes due to cavitation.

Another sign is unusual vibrations. These vibrations can wear down parts and cause them to fail. I also watch for changes in flow rate or pressure. These changes might mean cavitation is happening.

Impact of Pump Cavitation on Performance:

It’s key to understand how pump cavitation affects performance. This issue can cause big drops in efficiency, hurting productivity and raising costs. The damage from pressure changes creating vapor bubbles in the pump is clear.

Businesses often see their maintenance costs go up because of cavitation. They have to replace damaged parts often, which costs money and causes downtime. This can shorten the life of equipment, leading to early replacements.

Many industries struggle with pump systems because of cavitation. It can lead to unexpected maintenance, lowering efficiency and output. By knowing these effects, companies can take steps to keep their systems running well and stay profitable.

Preventing Pump Cavitation:

To prevent pump cavitation, we need a few key steps. First, we focus on the pump’s design. Choosing the right pump for the job is critical. The right size and type can greatly lower cavitation risks and boost performance.

Regular maintenance is also vital. I check pressure levels often to spot any changes that might signal cavitation. Checking fluid speeds in the system helps keep everything running right. These steps not only keep the pump safe but also make it last longer and work better.

By following these steps, we can keep our pumps working well and avoid cavitation problems. Paying close attention to design and upkeep ensures our pumps run smoothly for a long time.

Addressing Pump Cavitation Issues:

After spotting pump cavitation, the next move is to tackle it head-on. I start by checking the pump’s flow rates and inlet pressure. Making small tweaks to these can often fix the problem and get things running smoothly again.

Looking into ways to fix cavitation, I often find that raising the pump’s inlet pressure helps. Also, cutting down the system’s flow rate can lessen cavitation’s damage. If these fixes don’t work, I might need to look into pump repairs. Sometimes, just a small fix is needed, but other times, the pump needs to be replaced.

It’s important to act fast when dealing with cavitation to keep the system running well and avoid long downtime. By using these troubleshooting methods and exploring solutions, I can make the pumping system work better and last longer. Quick action not only stops problems but also saves money by avoiding costly pump failures.