In the world of fluid transfer, pump performance and efficiency are key. They ensure systems work well and save money. Important metrics like flow rate, head, and power consumption show how well a pump does its job.

Poor pump performance can raise costs and lower system efficiency. It’s vital to improve pump systems for better hydraulic and energy efficiency. By checking these metrics and following standards from groups like the Hydraulic Institute and the American Society of Mechanical Engineers, I can keep my systems efficient.

Understanding Pump Performance Metrics:

I dive into the key metrics that show how well a pump works. Flow rate is a big one, showing how much liquid a pump can move in a set time. It’s key to know if a pump can handle its job.

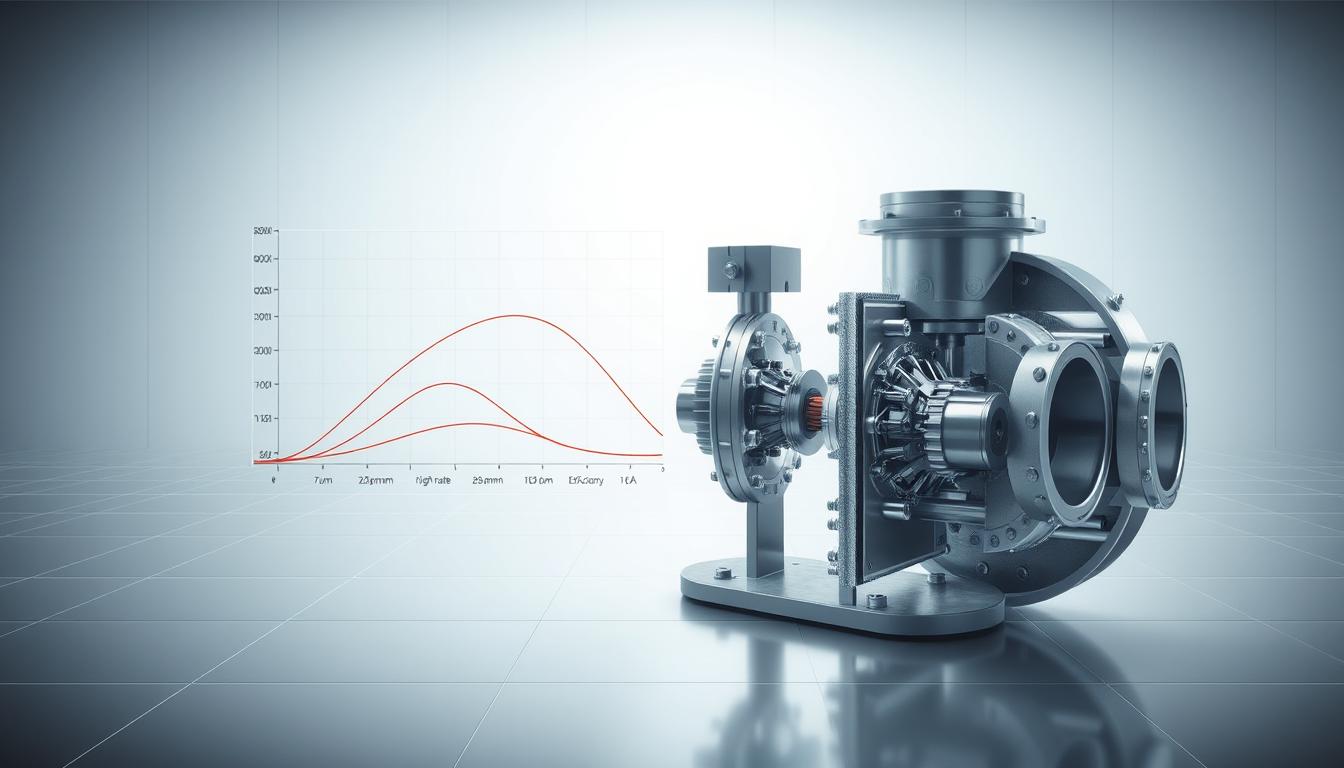

Head measurement is also vital. It tells us how much energy the pump adds to the fluid. By looking at flow rate and head together, I get a full picture of a pump’s performance. Efficiency curves help even more, showing how a pump does at different rates and pressures.

Net Positive Suction Head (NPSH) is another important factor. It makes sure the pump works right without getting damaged by cavitation. Knowing these metrics helps me choose and use pumps wisely, making sure they last a long time.

Factors Influencing Pump Efficiency:

Understanding the factors that affect pump efficiency is key. Hydraulic design, for example, plays a big role. The shape and size of impellers can change how well a pump works. If the design doesn’t match the application, efficiency can suffer a lot.

The fluid’s viscosity also matters a lot. Thicker fluids make it harder for the pump to move them, lowering efficiency. Temperature changes viscosity, affecting the pump’s performance. It’s important to think about these factors to keep the pump running well and saving energy.

To get the most out of a pump, it’s best to run it at its Best Efficiency Point (BEP). Companies like Grundfos and Flowserve use smart designs and systems to keep pumps running efficiently. This shows how important it is to optimize the pump’s operating point for better performance.

Pump Selection for Optimal Performance:

Choosing the right pump is key to getting the best results in different situations. It’s important to know exactly what you need before making a decision. Things like how much fluid you need to move, the pressure, and the type of fluid matter a lot.

Centrifugal pumps work well for moving a lot of fluid at low pressure. On the other hand, positive displacement pumps are better for precise, high-pressure tasks. Knowing this helps pick the best pump for the job.

Using pumps made for specific tasks can also save energy. By picking a pump that fits your needs perfectly, you can cut down on energy use. Looking at data from manufacturers helps compare options. Following standards like the ANSI/HI Pump Standards ensures you’re making a good choice.

Pump Maintenance and Efficiency Improvement:

Regular pump maintenance is key to keeping efficiency high. By sticking to service intervals, pumps work better and last longer. This helps avoid problems caused by wear and tear.

Regular checks let me spot issues early. This means I can fix problems fast and avoid long downtime. Keeping pumps running well saves money and ensures they work efficiently.

Knowing what each pump needs is important. I follow American Water Works Association guidelines or the manufacturer’s advice. This helps pumps last longer and reduces repair costs. Keeping pumps in good shape also boosts their performance.

Maximizing Efficiency in Pump Systems:

To boost pump system efficiency, I use strategies that cut down energy use and improve performance. One key method is using variable speed drives. These allow pumps to adjust their speed based on demand. This not only saves energy but also makes the equipment last longer by reducing stress.

System design is also vital for efficiency. I plan piping layouts to reduce bends and friction losses. Analyzing hydraulic designs ensures all parts work well together. This reduces pressure drops that harm pump performance. Companies like Xylem have shown how good design can save a lot of money.

By combining variable speed drives with smart design, pump systems work better. This approach not only boosts efficiency but also cuts down energy use. It shows the pump industry’s need for ongoing improvement, focusing on efficiency and sustainability.