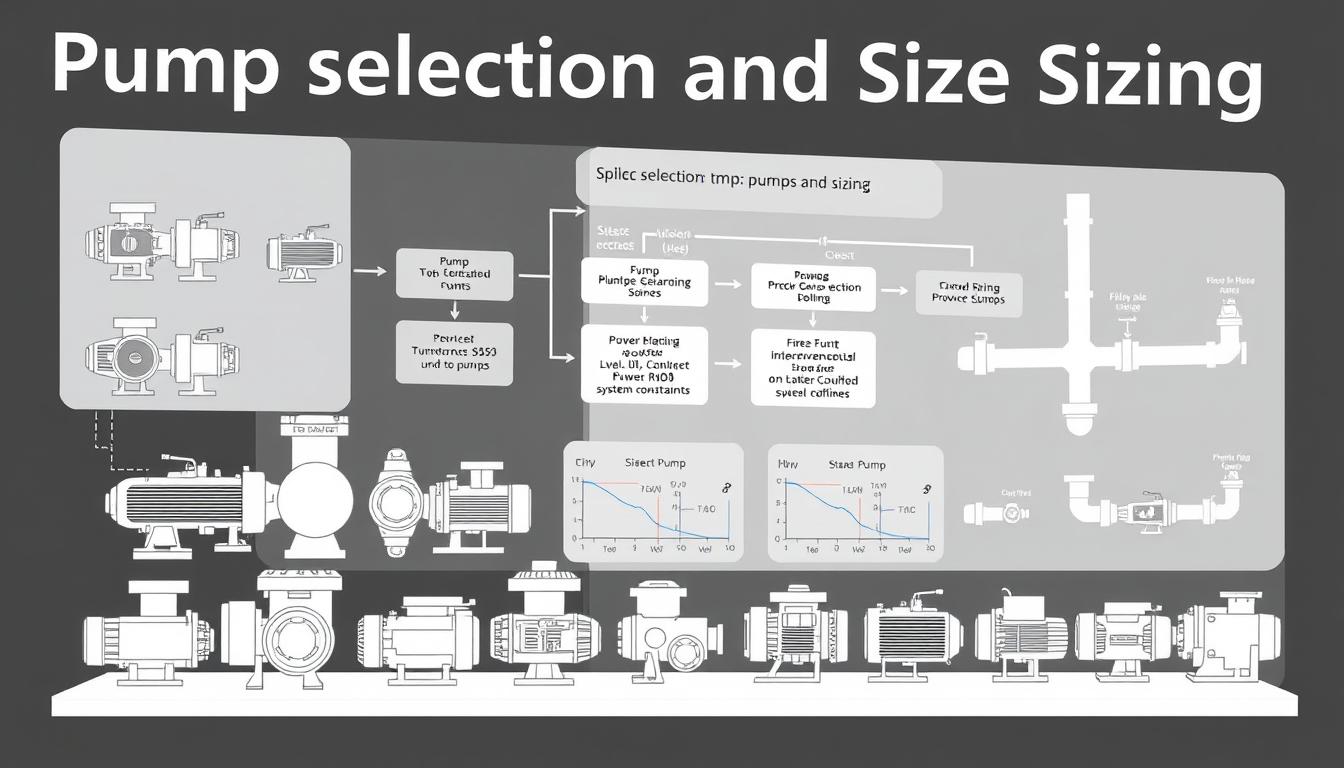

In the world of pump systems, picking the right pump is key for top performance and efficiency. I want to share the main points that guide us in choosing the best pump for each job. With so many choices, picking the wrong size can cause problems and increase costs. So, it’s vital to approach this with care and knowledge.

I’ll explore different types of pumps and why getting the size right is so important. This is true for both big industrial projects and homes. Let’s make sure we get it right for the best results.

Understanding Pump Types:

Exploring pump technology, I’ve learned that knowing the different types is key. There are mainly two categories: centrifugal pumps and positive displacement pumps. Centrifugal pumps are great for moving large amounts of fluid at lower pressures. They’re perfect for many uses.

Positive displacement pumps, on the other hand, work best in high-pressure situations. They keep the flow steady, no matter the pressure.

Submersible pumps are another vital type. They’re made to work underwater, which is why they’re essential for tasks like sewage treatment and getting groundwater. Knowing what each type offers helps me pick the right pump for my project.

Key Factors in Pump Sizing:

When sizing pumps, several key factors need careful thought to ensure the system works well. Flow rate and pressure are the most important. The flow rate must meet the application’s needs, or the system won’t work efficiently. The operating pressure also matters, affecting both performance and how long the system lasts.

The viscosity of the fluid is also key. Thicker fluids need pumps with special features to keep the flow rate right. Temperature can also change how the fluid flows and how the pump works.

Lastly, the application’s needs are critical. Each situation has its own challenges and needs. By looking at these factors closely, I can avoid problems and make sure the pumping system is reliable and efficient.

Pump Performance Curves:

Pump performance curves show how a pump works under different conditions. They plot flow rate against head, helping me see how a pump performs. It’s key to find the operating point, where the pump runs best in a system.

The pump performance curve and the system curve are linked for the best operation. The system curve shows how flow rate and pressure drop in the pipeline relate. By comparing these curves, I can see the pump’s efficiency at various flow rates and find the best operating point.

Choosing the right operating point is critical for efficiency and avoiding problems like cavitation or overload. When the pump performance curve matches the system curve, fluid transport is effective, and energy is saved. Understanding these concepts helps me make better choices for my pumping system’s performance.

Common Mistakes in Pump Selection:

In my experience, many pump selection errors happen during the sizing process. Oversizing or under sizing can make systems less efficient. This can hurt how well the system works.

Ignoring the total dynamic head (TDH) can cause big problems. I’ve seen cases where not considering fluid characteristics led to big issues.

Cavitation is another big problem that’s often ignored. Knowing if cavitation could happen is key. It can damage the pump and shorten its life. Proper installation and care can help avoid these problems and keep systems running well.

Calculating Total Dynamic Head:

Calculating total dynamic head (TDH) is key for hydraulic system efficiency. TDH is the height a pump must push fluid through the system. It includes static head and friction loss in pipes. Knowing how to measure these parts helps me pick the right pump.

Static head is the vertical distance from the fluid source to the discharge point. This is the base of TDH. To find head loss, I look at pipe length, diameter, material, and fluid viscosity. These details affect flow rates a lot.

Other pressure losses come from fittings, valves, and system parts. These add to the complexity of my calculations. By understanding all parts of TDH, I can choose a pump that works well in the system.

Pump Accessories and Add-ons:

Choosing the right pump accessories and add-ons can really make a difference. Variable frequency drives (VFDs) are key for saving energy and working well with control systems. They adjust the motor speed to make pumps work their best.

Monitoring devices are also important. They let users see how pumps are doing in real time. This helps spot problems early and keeps systems running smoothly. It also saves money by avoiding unexpected repairs.

Using these accessories and add-ons can cut down on costs over time. Pick the right ones to make your system better. Knowing how to use these tools can really improve your pump’s performance.

Real-World Applications of Pumps:

Pumps are key in many industries, improving how things work. In cities, municipal pumps move water from treatment plants to homes. This ensures everyone gets clean water, which is vital for health and infrastructure.

In HVAC systems, the right pumps are essential. They help fluids move through systems, keeping temperatures right. This makes spaces comfortable and saves energy costs.

In chemical plants, the right pump is critical. For example, in places with harsh chemicals, the right pump lasts longer and needs less upkeep. Studies show that choosing the right pump boosts reliability and performance, showing how important it is to pick the right one.